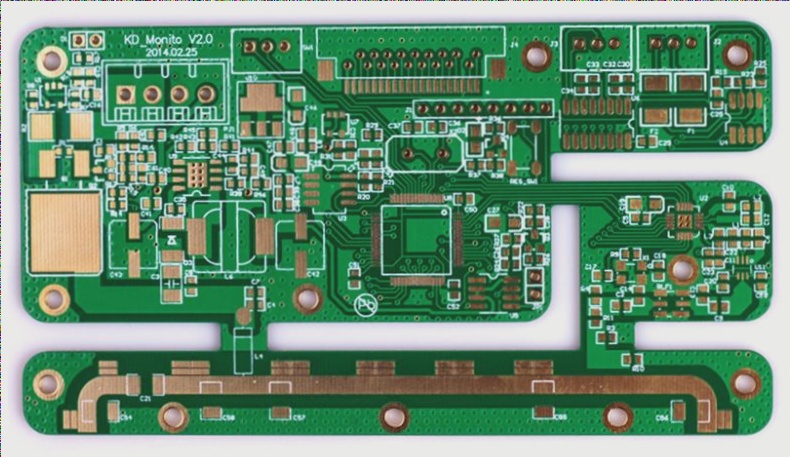

Judging from appearance

1. Weld Appearance

With the numerous parts on a PCB circuit board, it is crucial for the welding to be done securely to prevent parts from falling off easily, which can greatly impact the overall quality and appearance of the circuit board.

2. Dimension and Thickness Standards

PCBs come in different thicknesses as per standard rules. Users can measure and verify according to their specific requirements.

3. Light and Color

The external PCB circuit boards are typically covered with ink for insulation. A dull color indicates a lack of ink, which can affect the quality of the insulation board itself.

Judging from the board

1. HB board is inexpensive but prone to deformation and breakage, suitable for single panels with a deep yellow component surface color and a rough, thin copper coating.

2. Single-sided 94V0, CEM-1 boards are relatively more expensive than cardboard, with a light yellow component surface color, commonly used for industrial and power boards with fire rating requirements.

3. FR4 boards have a high cost and good strength, with a green double-sided appearance. Most PCBs are made from this material, offering precise and fine copper coating, albeit being heavier than unit boards. The printing ink on PCB circuit boards should be smooth, with no false wire dew copper or bubbling.

WellCircuits is a high-tech enterprise focused on providing customers with comprehensive high-end printed circuit board manufacturing services, from sample R&D to mass production. We offer faster delivery at the same cost and can also fulfill orders at a lower cost with similar speed. Additionally, we provide CAD design, PCBA processing, and component procurement services to meet market and customer needs. Our service centers are established in major domestic electronic product design centers, and we have served over 3,000 customers worldwide with rapid electronic manufacturing services.

Through years of dedication, WellCircuits has built a unique one-stop electronic manufacturing service platform and has attracted a team of industry seniors. With extensive experience and training, we have developed a production and technical service team with excellent compound abilities. Our business spans CAD design, PCB manufacturing, PCBA processing, and component supply—providing clients with a convenient one-stop shopping experience, improving procurement efficiency, and reducing supply chain costs while ensuring reliable product quality. Our products are widely applied in industrial control, power, national defense, medical, automotive, security, and computer industries. We are committed to fast delivery, rooted in excellent product quality, empowered by lean manufacturing processes, and praised for our professional service by our customers.

As an innovative one-stop high-end electronics manufacturing service expert, WellCircuits LIMITED is dedicated to providing a more convenient experience, intimate services, and ongoing innovation and progress for our customers.

1. Weld Appearance

With the numerous parts on a PCB circuit board, it is crucial for the welding to be done securely to prevent parts from falling off easily, which can greatly impact the overall quality and appearance of the circuit board.

2. Dimension and Thickness Standards

PCBs come in different thicknesses as per standard rules. Users can measure and verify according to their specific requirements.

3. Light and Color

The external PCB circuit boards are typically covered with ink for insulation. A dull color indicates a lack of ink, which can affect the quality of the insulation board itself.

Judging from the board

1. HB board is inexpensive but prone to deformation and breakage, suitable for single panels with a deep yellow component surface color and a rough, thin copper coating.

2. Single-sided 94V0, CEM-1 boards are relatively more expensive than cardboard, with a light yellow component surface color, commonly used for industrial and power boards with fire rating requirements.

3. FR4 boards have a high cost and good strength, with a green double-sided appearance. Most PCBs are made from this material, offering precise and fine copper coating, albeit being heavier than unit boards. The printing ink on PCB circuit boards should be smooth, with no false wire dew copper or bubbling.

WellCircuits is a high-tech enterprise focused on providing customers with comprehensive high-end printed circuit board manufacturing services, from sample R&D to mass production. We offer faster delivery at the same cost and can also fulfill orders at a lower cost with similar speed. Additionally, we provide CAD design, PCBA processing, and component procurement services to meet market and customer needs. Our service centers are established in major domestic electronic product design centers, and we have served over 3,000 customers worldwide with rapid electronic manufacturing services.

Through years of dedication, WellCircuits has built a unique one-stop electronic manufacturing service platform and has attracted a team of industry seniors. With extensive experience and training, we have developed a production and technical service team with excellent compound abilities. Our business spans CAD design, PCB manufacturing, PCBA processing, and component supply—providing clients with a convenient one-stop shopping experience, improving procurement efficiency, and reducing supply chain costs while ensuring reliable product quality. Our products are widely applied in industrial control, power, national defense, medical, automotive, security, and computer industries. We are committed to fast delivery, rooted in excellent product quality, empowered by lean manufacturing processes, and praised for our professional service by our customers.

As an innovative one-stop high-end electronics manufacturing service expert, WellCircuits LIMITED is dedicated to providing a more convenient experience, intimate services, and ongoing innovation and progress for our customers.