Flex boards and rigid boards are the two main materials commonly used in electronic products, and they have significant differences in physical properties, scope of use, and applicable scenarios. Flex boards are characterized by their flexibility and bendability, making them suitable for scenarios that require bending and folding. On the other hand, rigid boards are known for their hardness and stability, making them suitable for scenarios that require stability and durability. There are also differences in manufacturing processes, costs, reliability, and other aspects between flex and rigid boards. By comparing flex boards and rigid boards, we can gain a better understanding of their characteristics and application areas. As a PCB expert, I can help you understand the differences and advantages of using flex and rigid boards in your electronic products. The Difference Between Rigid Boards and Flex Boards

The Difference Between Rigid Boards and Flex Boards

1. Differences in Physical Properties

There are significant differences in physical properties between flex boards and rigid boards.

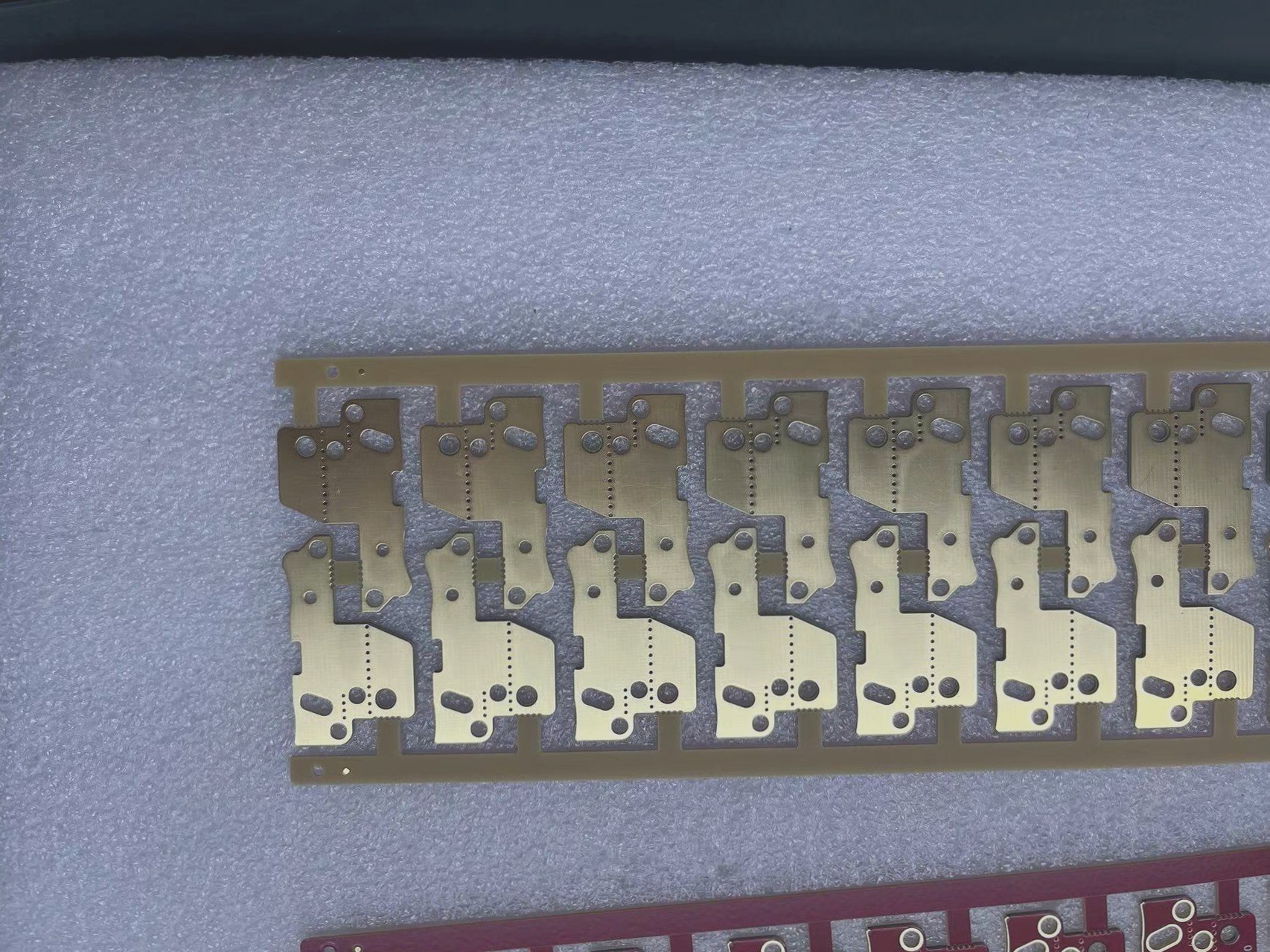

1) Flex boards are typically made of flexible materials, such as polyimide (PI) film and polyester film, which offer good flexibility and bendability.

2) On the other hand, rigid boards are usually constructed from hard materials like fiberglass, ceramics, and metals, providing high hardness and stability.

2. Differences in Usage Scope

There are also variations in the scope of use between flex and rigid boards.

1) Rigid boards are suitable for applications requiring bending and folding due to their flexibility. For instance, flexible display screens and foldable phones use flex boards as their basic material.

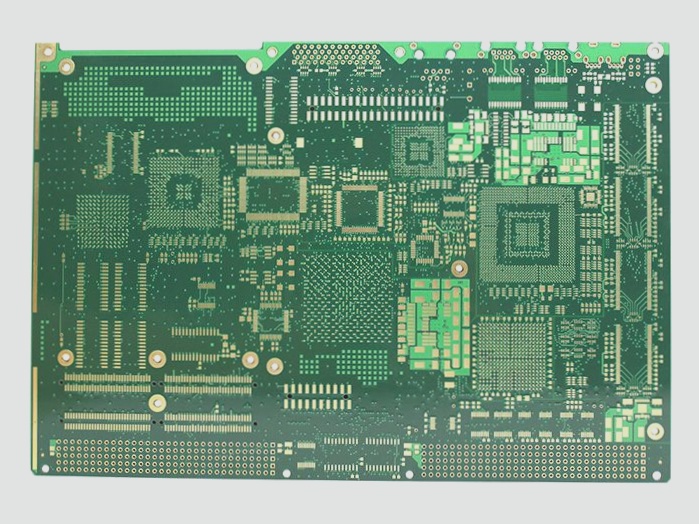

2) Rigid boards, with their rigidity and stability, are suitable for scenarios requiring durability and stability, such as computer motherboards and electronic device casings.

3. Differences in Applicable Scenarios

There are differences in applicable scenarios between flex and rigid boards as well.

1) Flex boards are suitable for scenarios requiring bending and folding, offering greater portability and flexibility. For example, a bendable display screen can be adjusted according to user needs.

2) On the other hand, due to their stability, rigid boards are suitable for applications demanding stability and durability. For instance, computer motherboards need to stably support various hardware devices, necessitating the use of rigid boards to ensure stability and reliability.

4. Differences in Manufacturing Processes, Costs, and Reliability

There are also disparities in manufacturing processes, costs, and reliability between flex and rigid boards.

1) The manufacturing process of flex boards is relatively simple and can be produced through printing, film lamination, and other methods, resulting in relatively low costs.

2) In contrast, the manufacturing process of rigid boards is relatively complex, involving multiple processing and assembly steps, resulting in higher costs. Additionally, flex boards, due to their flexibility, are more susceptible to environmental influences during use, leading to relatively lower reliability. However, rigid boards, with their stability and hardness, offer higher reliability.

A rigid board serves as the support body in electronic components, typically utilizing FR4 as the substrate and cannot be bent, as seen in computer motherboards and mobile phone motherboards.

Meanwhile, flex boards generally use PI as the substrate, a flexible material with excellent qualities such as lightweight, thin thickness, and inherent ability to bend and fold. PCB flex boards can be connected through terminal connections, or a combination of flex and rigid boards. Many rigid boards can be configured and connected using layout methods.

The Difference Between Rigid Boards and Flex Boards

The Difference Between Rigid Boards and Flex Boards1. Differences in Physical Properties

There are significant differences in physical properties between flex boards and rigid boards.

1) Flex boards are typically made of flexible materials, such as polyimide (PI) film and polyester film, which offer good flexibility and bendability.

2) On the other hand, rigid boards are usually constructed from hard materials like fiberglass, ceramics, and metals, providing high hardness and stability.

2. Differences in Usage Scope

There are also variations in the scope of use between flex and rigid boards.

1) Rigid boards are suitable for applications requiring bending and folding due to their flexibility. For instance, flexible display screens and foldable phones use flex boards as their basic material.

2) Rigid boards, with their rigidity and stability, are suitable for scenarios requiring durability and stability, such as computer motherboards and electronic device casings.

3. Differences in Applicable Scenarios

There are differences in applicable scenarios between flex and rigid boards as well.

1) Flex boards are suitable for scenarios requiring bending and folding, offering greater portability and flexibility. For example, a bendable display screen can be adjusted according to user needs.

2) On the other hand, due to their stability, rigid boards are suitable for applications demanding stability and durability. For instance, computer motherboards need to stably support various hardware devices, necessitating the use of rigid boards to ensure stability and reliability.

4. Differences in Manufacturing Processes, Costs, and Reliability

There are also disparities in manufacturing processes, costs, and reliability between flex and rigid boards.

1) The manufacturing process of flex boards is relatively simple and can be produced through printing, film lamination, and other methods, resulting in relatively low costs.

2) In contrast, the manufacturing process of rigid boards is relatively complex, involving multiple processing and assembly steps, resulting in higher costs. Additionally, flex boards, due to their flexibility, are more susceptible to environmental influences during use, leading to relatively lower reliability. However, rigid boards, with their stability and hardness, offer higher reliability.

A rigid board serves as the support body in electronic components, typically utilizing FR4 as the substrate and cannot be bent, as seen in computer motherboards and mobile phone motherboards.

Meanwhile, flex boards generally use PI as the substrate, a flexible material with excellent qualities such as lightweight, thin thickness, and inherent ability to bend and fold. PCB flex boards can be connected through terminal connections, or a combination of flex and rigid boards. Many rigid boards can be configured and connected using layout methods.