DIY Reflow Soldering Issue: Solder Balls Formation

When conducting my own reflow soldering, I consistently encounter a common issue that, while not critical, proves to be quite bothersome. I’m seeking advice on why this occurs and how I can potentially address it myself.

My reflow process involves a controller and a small oven. The crux of the matter is that during reflow, solder tends to extrude from the pads, forming small balls around the component edges. This issue occurs frequently across various component types and sizes, including capacitors, resistors, and ICs. These solder balls remain in the flux residue post-reflow, raising concerns about potential short circuits or leakage paths.

My initial assumption is that this issue may stem from either the solder quantity (possibly related to stencil thickness) or a mismatch between the solder type and the reflow profile. However, I lack clarity on which factor is the root cause and how to proceed. If the stencil were to blame, I speculate that others sourcing from the same supplier would encounter similar problems.

To address this, I have been manually removing and cleaning each solder ball post-reflow. While manageable, there is always a risk of oversight, making it a somewhat tedious task. Any insights or suggestions on resolving this issue would be greatly appreciated.

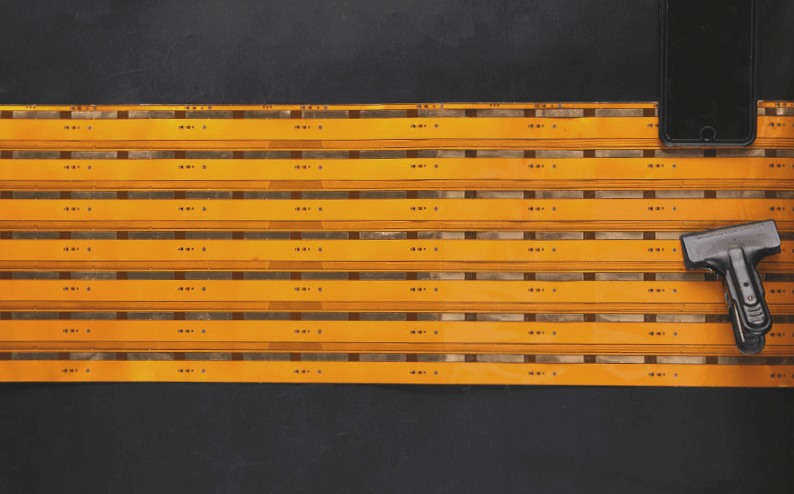

Explore the image below for a visual representation of the solder ball formation phenomenon:

Seeking Solutions for Reflow Soldering Challenges

Have you encountered solder ball formation issues during reflow soldering? Learn more about potential causes and remedies to enhance your DIY soldering process.