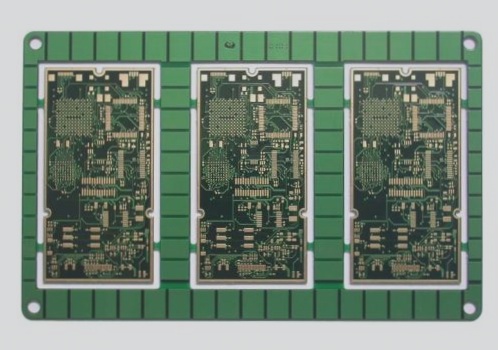

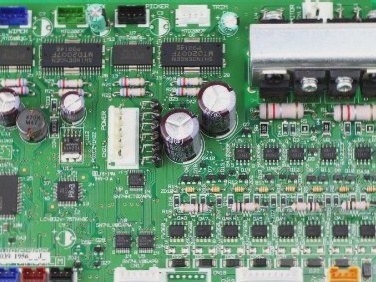

Understanding Vias and Annular Rings in PCB Design

When it comes to vias in PCB design, the annular rings play a crucial role in connecting different layers. But have you ever wondered if annular rings are necessary for all layers a via passes through?

For instance, if you are routing a signal from the top layer to layer 3, do you need annular rings on layer 2 and the bottom layer as well? Understanding the manufacturing process can provide insights into this.

When working with components like BGAs for the first time, the significance of annular rings on vias may not be immediately clear. Leaving them as they are might limit your routing options. Tools like Altium allow you to customize the annular ring size for each layer, providing flexibility in your design.

For example, when routing a 0.8mm Xilinx FPGA BGA with 4mil traces and 0.2mm vias, adhering to a 6 mil annular ring as per the manufacturer’s specifications can help reduce costs for standard boards. However, opting for advanced production processes may significantly increase the overall board cost.

Exploring the settings for vias in Altium can offer valuable insights into optimizing your PCB design.