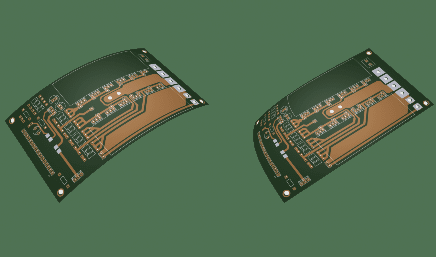

1. After demonstrating how to calculate the bending radius for a single-layer flex PCB, we will now explain how to do it for a double-sided FPC.

In the picture:

R=minimum bending radius, unit µm

c=copper skin thickness, unit µm

D=covering film thickness, unit µm

EB=copper skin deformation, measured in percentage.

The value of EB is the same as above.

D=thickness of interlayer dielectric, unit µm

The minimum bending radius and flexural strength of FPC type minimum bending radius:

1. Single panel 3~6 times the thickness of the wire

2. Double-sided board 6~10 times the thickness of the wire

3. Multilayer flexible board 10~15 times the thickness of the wire.

4. Dynamic single panel 20-40 times the thickness of the wire

In the picture:

R=minimum bending radius, unit µm

c=copper skin thickness, unit µm

D=covering film thickness, unit µm

EB=copper skin deformation, measured in percentage.

The value of EB is the same as above.

D=thickness of interlayer dielectric, unit µm

The minimum bending radius and flexural strength of FPC type minimum bending radius:

1. Single panel 3~6 times the thickness of the wire

2. Double-sided board 6~10 times the thickness of the wire

3. Multilayer flexible board 10~15 times the thickness of the wire.

4. Dynamic single panel 20-40 times the thickness of the wire