1. COB bonding processing involves fixing the IC die wafer onto the PCB board using a COB bonding machine, also known as chip-on-board packaging.

2. Afterward, aluminum wire or packaging pins are employed to connect the die to the PCB.

3. Typically, the COB wafer is bonded after the circuit is connected to the wafer pins, followed by packaging the chip with black, white, or red glue.

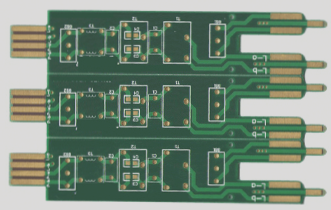

4. It’s important to note that the PCB board should only use gold-plated, immersion gold, or nickel-plated processes, and must avoid tin-spraying methods.

5. The distinctive aspect of COB bonding technology is that the finished material cost is generally lower than that of SMT patch processing, though the labor costs for COB bonding tend to be higher.

6. So, what are the auxiliary materials used in COB bonding? There are mainly four types of auxiliary materials, and now let’s explore these together!

—

Let me know if you need any further adjustments!

1. **Aluminum wire:** The aluminum wire we utilize is a blend of aluminum and silicon, featuring 1mil and 1.25mil variants. Operators should avoid touching the wire on the spool during disassembly; the starting end typically emerges with a red band indicator. Different models have distinct threading paths, which connect the circuit pads on the chip to the PCB.

2. **Steel mouth:** The steel mouth is crafted from specialized steel, hence the name. A small hole at the lower end allows the aluminum wire to pass through. Care should be taken not to strike the steel mouth with any objects during operation to prevent damage. Its purpose is to press and weld the aluminum wire, forming and securing it according to standard specifications.

3. **Red glue:** Red glue is a high-strength adhesive that becomes oil-proof, waterproof, shockproof, and resistant to corrosion upon curing. It is ideal for bonding bare chips (ICs) to other metals, ensuring the chip is securely attached to the PCB as required.

4. **Black glue:** Black glue is an epoxy resin encapsulation material known for its high reliability. It is suitable for COB encapsulation of semiconductor components, providing protection against damage from adverse external conditions.

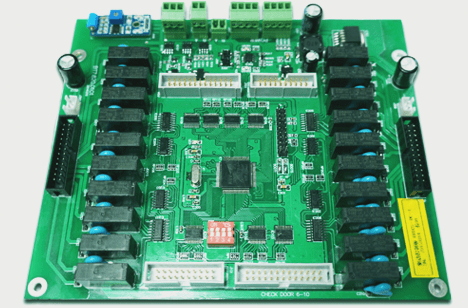

Some may wonder if the special eraser for circuit boards qualifies as an auxiliary material for the IC bonding machine. Indeed, it is essential for the process flow. COB bonding involves using a bonding machine to connect the bonding IC to the circuit board with a bonding wire, including steps like board scanning, dispensing red glue, attaching the IC, bonding, pre-testing, sealing, baking, and post-testing. Circuit boards requiring COB bonding are commonly used in thermometers, clinical thermometers, skipping ropes, calipers, electronic scales, and multimeters.