1. The invention pertains to the domain of PCB board manufacturing, specifically focusing on the process of plating the sides of PCB boards with gold and utilizing electroplating for nickel and gold.

2. As the industry evolves, an increasing number of electronic products are adopting bonding processes to reduce product size, leading to a rise in the use of electroplated nickel-gold surface finishes on PCBs.

3. In the mainstream production process, the gold-plated finger technique enables the gold-cladding of solder joints; however, it requires the separate fabrication of lead-through solder joints and board edges, which are subsequently removed after gold plating.

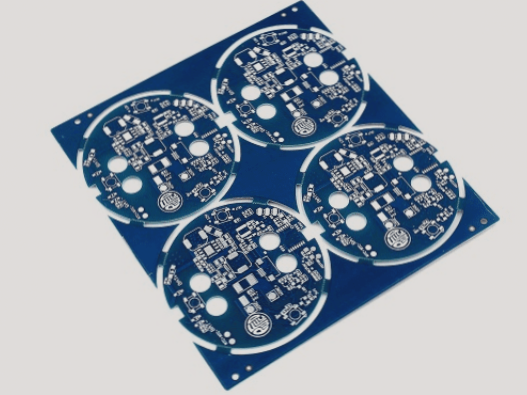

4. This method is primarily suitable for producing gold-clad solder joints on the board’s sides.

5. The electroplating process for nickel and gold is straightforward, eliminating the need for separate lead creation, but it only allows gold plating on the top layer of solder joints, making it unsuitable for producing gold plating on the plate side.

—

Let me know if you need further adjustments!

1. **Technical Realization Elements:** The invention presents a PCB board side gold-clad nickel-gold electroplating process, enabling simultaneous top layer gold plating and board side gold-cladding.

2. To address the aforementioned challenges, this invention introduces a gold-clad nickel-gold electroplating process on the circuit board’s side. This involves creating an etching groove on the copper surface through etching, extending the gold-clad pattern to expose the sidewalls of the copper layer that require gold coating.

3. A dry film is applied to the copper layer, with a window created on the film that aligns with the etching groove and the copper area needing gold plating, thereby exposing the side wall.

4. The PCB board undergoes nickel and gold electroplating, resulting in both the copper area and the side wall receiving a layer of nickel gold.

5. **Detailed Methods:** The embodiments of this invention will be elaborated upon with reference to accompanying drawings, though the invention can be implemented in various ways as defined in the claims.

6. One aspect of the invention details a gold-clad nickel-gold electroplating process on the PCB board’s side. The pattern is designed to expose the sidewalls of the copper layer that need gold coating.

7. A dry film is applied to the copper layer, and an opening is created that corresponds to the etching groove and the copper area that requires gold plating, thus exposing the side wall.

8. The circuit board is then electroplated with nickel and gold, ensuring both the copper area and the side wall are coated with a layer of nickel and gold.

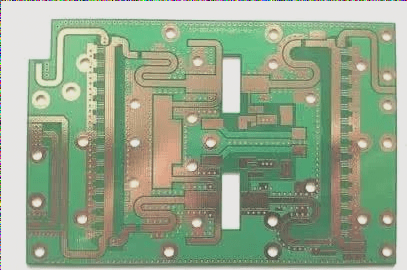

9. In manufacturing the circuit board, as depicted in Figure 1, a dry film is applied to the outer side of the copper layer, followed by creating an opening that corresponds to the desired etching groove.

10. Subsequently, etching is performed to form the etching groove, where one side wall requires gold cladding in the next step.

11. A dry film is then affixed to the outer wall of the copper layer, incorporating an opening that aligns with the copper area designated for gold plating and the surrounding etching groove.

12. Finally, the PCB board undergoes electroplating. As the upper and side surfaces of the copper area are not covered by the dry film at this stage, nickel and gold can be deposited on both the upper surface and the sidewalls simultaneously, achieving both top layer and board edge gold plating.