Understanding Rigid-Flex PCBs and Surface Treatment Methods for Aluminum Substrates

Rigid-flex PCBs offer a unique combination of durability and flexibility, making them ideal for challenging environmental conditions in medical and military equipment manufacturing.

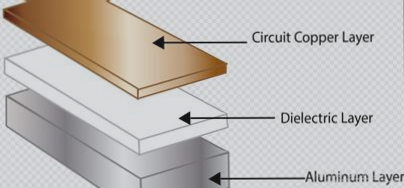

Enhancing Reliability with Aluminum Substrates

Aluminum rigid-flex substrates provide superior heat dissipation and longer lifespan compared to standard FR-4 substrates. The bonding strength of PCBs is crucial for reliability, emphasizing the need for effective surface treatment methods on aluminum substrates.

Exploring Surface Treatment Methods

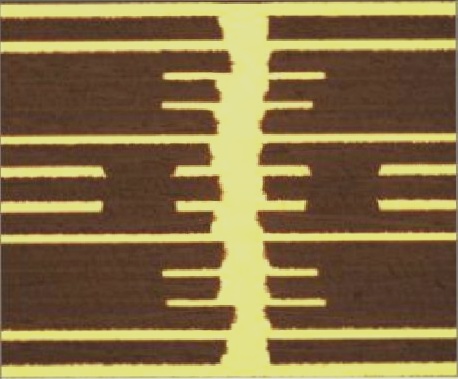

Surface treatment techniques for aluminum substrates include physical grinding & brushing methods and chemical etching methods, aiming to enhance adhesion between materials.

Physical Grinding & Brushing

Methods like nonwoven fabric grinding brushes, volcanic ash grinding brushes, and sanding belt grinding create a rough texture on aluminum surfaces.

- Nonwoven fabric grinding brushes

- Volcanic ash grinding brushes

- Sanding belt grinding

Chemical Etching

Chemical etching involves using alkaline solutions to roughen the aluminum surface, requiring careful control of solution concentration and reaction time.

Measuring Surface Roughness

Surface roughness on aluminum substrates can be measured through contact and non-contact methods, with non-contact techniques providing accurate data without damaging the surface.

Conclusion: The surface treatment of aluminum substrates should balance roughness levels for optimal adhesion, with alkaline etching offering uniform micro-rough surfaces for enhanced reliability.

- Research shows that aluminum substrates undergo alkaline etching before compression have demonstrated superior resistance to aging and exceptional adhesion strength, ensuring optimal reliability for final products.

- Various surface treatment alternatives are accessible. For large-scale production, methods that offer high output, efficiency, and cost-effectiveness are favored. In cases where necessary, combined treatments can be implemented to fulfill the product’s reliability standards.

If you have any inquiries regarding PCBs or PCBA, please don’t hesitate to reach out to me via info@wellcircuits.com.