Understanding Impedance in PCB Boards

As a PCB specialist, I focus on resistance and reactance parameters that affect the flow of alternating current in circuit boards. Impedance management is crucial in PCB production to ensure optimal performance.

Why Reactance Matters

Reactance hinders current flow in PCB boards, impacting overall functionality. It is necessary to address reactance issues to maintain efficient circuit operation.

Factors Affecting Impedance

- During production, processes like copper sinking, tin electroplating, and connector soldering are essential. Materials with low resistivity are crucial to minimize impedance and meet quality standards.

- Tin plating is a critical step that can affect impedance. Issues like discoloration, poor solderability, and high impedance can impact board performance.

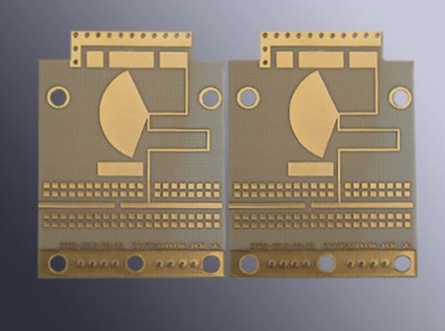

- Conductors on the board play a vital role in signal transmission. Changes in impedance due to etching, stack thickness, and wire width can distort signals, requiring precise impedance control.

- When installing components, lower impedance is preferred to enhance electrical performance and signal transmission.

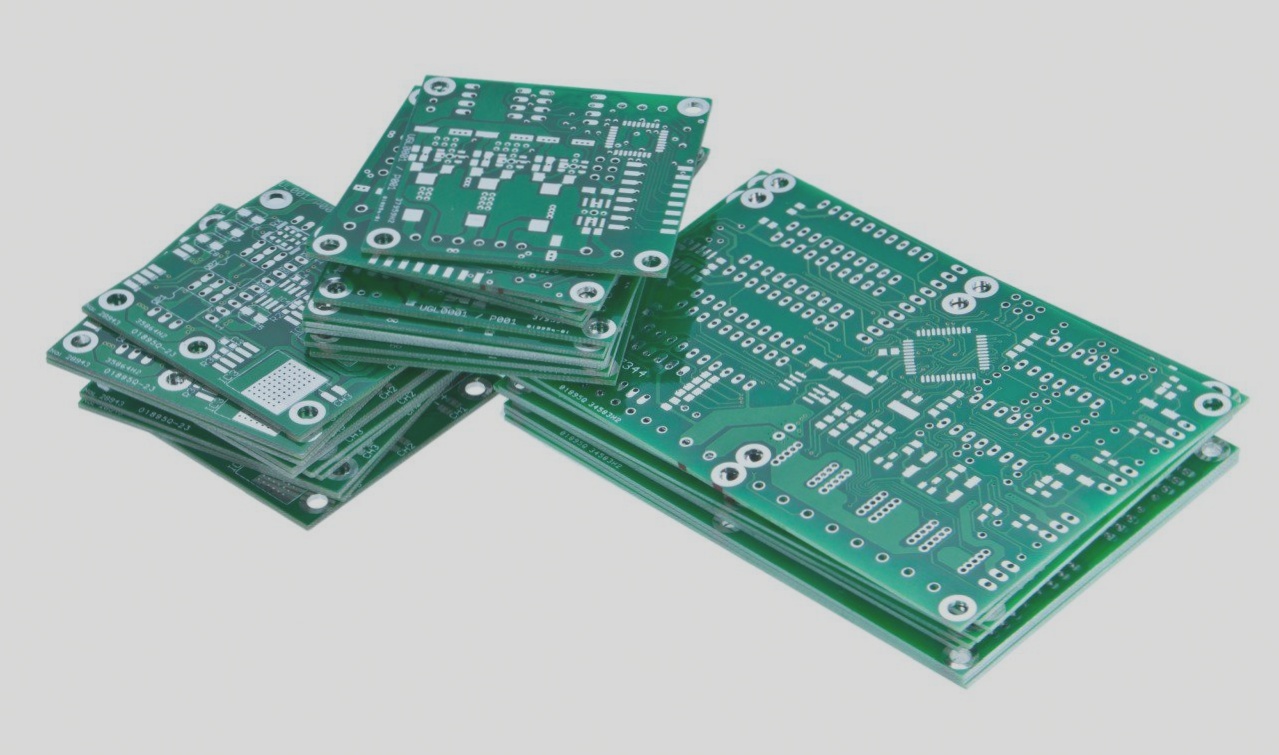

WellCircuits Limited: Your PCB Solution

WellCircuits Limited specializes in manufacturing high-precision circuit boards, including double-sided, multi-layer, impedance-controlled, and thick copper boards. Their product range covers HDI, thick copper, backplanes, rigid-flex, and more, catering to various customer requirements.