Advancing Electric Vehicle Charging Stations with PCB Layout and Assembly

Electric vehicles (EVs) are gaining popularity in the UK, leading to the emergence of new modifications in vehicle charging stations. These changes aim to maximize the benefits of reducing gasoline consumption and align with the growing trend of environmental awareness and the use of eco-friendly products.

The Role of PCB Layout and Assembly in Driving Innovation

As more people choose plug-in hybrid or electric vehicles, understanding Plug-in Electric Vehicles (PEVs) becomes crucial. Battery electric vehicles rely solely on electric motors, while plug-in hybrid electric vehicles combine an electric motor with a gasoline engine. PEVs require regular charging for optimal performance and mileage.

Researchers anticipate a shift from traditional gas stations to electric vehicle charging stations due to the increasing adoption of PEVs. This transition emphasizes the significance of electricity as a primary fuel source for vehicles, particularly in the UK. The challenge lies in developing efficient and innovative solutions for car charging stations, propelling the electronics industry forward.

Enhancing Charging Stations through PCB Manufacturing

PCB manufacturing plays a pivotal role in enhancing the design and functionality of charging stations. Addressing the shortage of charging stations in various locations is essential to support the growing number of electric vehicles. Both free and paid charging options are becoming key features of these stations.

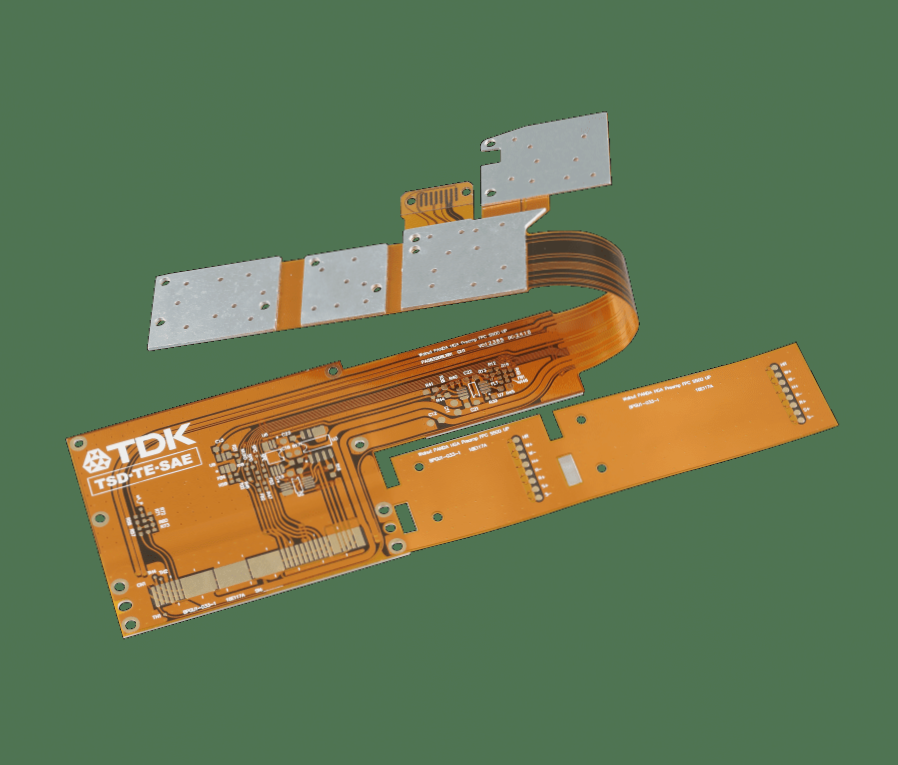

To unlock the full potential of electric vehicles, advanced PCB prototypes are essential for designing charging stations for diverse settings, including homes, commercial spaces, and public areas. These prototypes offer multi-functional capabilities and can be customized to meet specific requirements, such as wall-mounted designs and various charging station structures.

Key Developments in Electric Vehicle Charging Stations

- Manufacturing versatile commercial charging devices with options for fast charging and heavy-duty vehicle support using flexible PCBs.

- Implementing automatic charging and payment systems with embedded controllers for NFC and Internet connectivity, focusing on cost-efficiency and high performance.

- Introducing EV control centers with paid and free charging options managed through a central control panel for seamless user experience.

- Utilizing cutting-edge PCB components and production technologies to create compact and efficient printed circuit boards for advanced EV control systems.

This revised version maintains the original content structure while enhancing clarity and relevance, focusing on the role of PCB layout and assembly in shaping the future of electric vehicle charging stations.