Electromagnetic Compatibility (EMC) in PCB Design

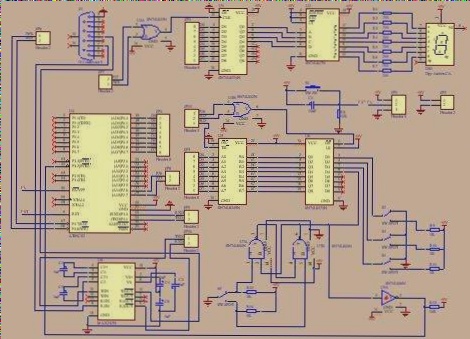

Electromagnetic compatibility (EMC) is crucial for ensuring that a PCB device operates effectively within its electromagnetic environment without causing interference to other equipment. Achieving EMC involves minimizing electromagnetic emissions and protecting the system from external electromagnetic interference (EMI). To address EMC successfully, it is essential to manage interference sources, coupling paths, and receivers effectively.

Latest Developments in EMC Design

EMC design in PCB engineering is intricately linked to circuit characteristics. Design engineers focus on reducing electromagnetic radiation and enhancing the product’s immunity to radiation. The primary goal is to improve the device’s resistance to electromagnetic interference (EMI) and ensure proper shielding. Effective EMC design addresses low-frequency conduction and high-frequency radiation coupling, emphasizing the importance of cutting off interference propagation paths.

Key Principles for PCB Anti-Interference Design

- Suppressing Interference Sources: This involves reducing voltage and current changes in digital devices by using capacitors and inductors strategically.

- Cutting Off Interference Propagation Path: Engineers focus on power supply noise control, crystal oscillator layout, circuit board partitioning, and grounding strategy to enhance EMC performance.

- Enhancing Immunity of Sensitive Devices: Strategies include minimizing interference pickup and enabling quick recovery from abnormal conditions.

By implementing these principles, PCB designers can create systems that meet EMC standards and operate reliably in their electromagnetic environments.

PCB Design Best Practices for EMI Mitigation

- I/O Port Handling: To prevent unwanted noise, it is crucial to ground or connect unused I/O ports of microcontrollers to the power supply instead of leaving them floating.

- Power Supply Monitoring: Implementing a power supply monitoring circuit can enhance the circuit’s immunity to interference by detecting and compensating for power fluctuations and noise.

- Lowering Clock Speeds: Reducing the microcontroller’s clock frequency or opting for lower-speed digital circuits can decrease susceptibility to EMI, as lower speeds result in reduced noise generation.

- Direct Soldering of ICs: It is advisable to solder ICs directly onto the PCB to minimize parasitic inductance and resistance, which can impact signal integrity.

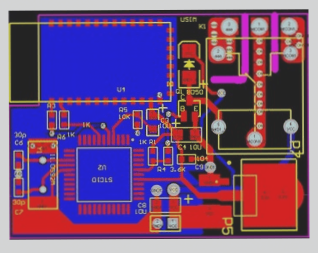

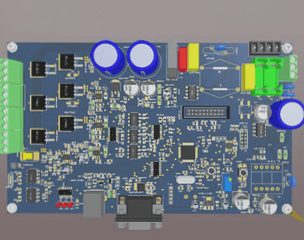

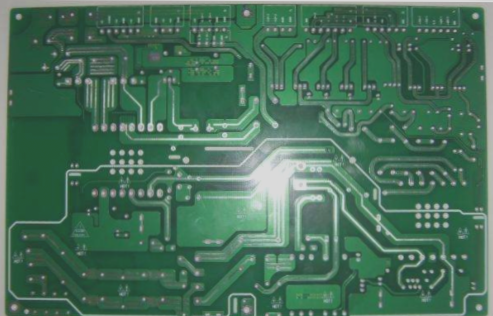

PCB Prototyping and Surface Treatment

PCB prototyping, also known as PCB proofing, involves producing trial versions of printed circuit boards before mass production. This step is crucial for testing and refining circuit designs before finalizing the product. Surface treatment options for high-quality solderability and electrical performance include:

- Hot Air Leveling (HASL): A common method providing good solderability at a reasonable cost.

- Electroless Plating: Processes like immersion silver, immersion gold, and Ni/Pd/Au ensure high-quality, long-lasting surface finishes, especially for high-frequency applications.

- Nickel and Gold Plating: Full-board nickel-gold plating is ideal for boards needing excellent electrical properties and durability.

When selecting a surface treatment method, engineers should consider the PCB manufacturer’s production capabilities and service levels to ensure the chosen process aligns with design and functional requirements.

Conclusion

To achieve electromagnetic compatibility in PCB design, a comprehensive understanding of interference sources, propagation paths, and component sensitivity is essential. By adhering to principles that suppress interference, cut off propagation paths, and enhance component immunity, engineers can develop PCBs that perform reliably in electromagnetically challenging environments. Prototyping and surface treatment stages play a vital role in testing and ensuring the final design meets performance and manufacturability standards.