PCB Failure Analysis Techniques

- Visual Inspection

- X-ray Fluoroscopy

- Slice Analysis

- Scanning Acoustic Microscope

- Micro-Infrared Analysis

- Scanning Electron Microscope Analysis

- X-ray Energy Spectrum Analysis

- Photoelectron Spectroscopy (XPS) Analysis

- Thermal Analysis Differential Scanning Calorimetry (DSC)

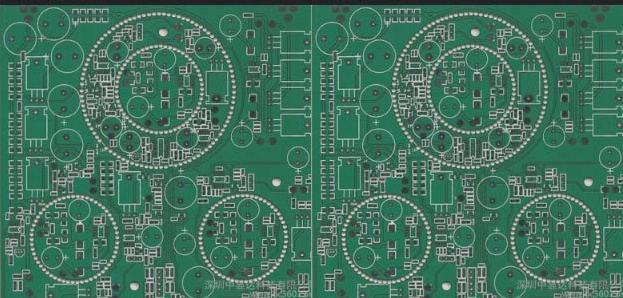

Visual inspection involves using instruments like microscopes to identify PCB board failures, contamination, corrosion, and wiring irregularities.

X-ray fluoroscopy detects internal defects within PCBs, such as solder joints and faulty device soldering, using X-ray absorption principles.

Slice analysis provides detailed insights into PCB structures by obtaining cross-sectional samples, although it is a destructive process.

Scanning acoustic microscopes analyze electronic assemblies for defects like cracks and delamination using high-frequency ultrasound reflections.

Micro-infrared analysis combines spectroscopy and microscopy to identify organic contaminants affecting PCB solderability.

Scanning electron microscopes provide high-resolution imaging for assessing solder joint quality and tin whisker growth.

X-ray energy spectrum analysis identifies elements on PCB surfaces affecting solderability through characteristic X-ray emissions.

XPS offers insights into PCB coating quality and pollutants through X-ray-induced electron emissions.

DSC measures material properties critical for PCB reliability, such as polymer curing and glass transition temperatures.

Latest Updates:

Recent advancements in PCB failure analysis include the integration of artificial intelligence algorithms for quicker and more accurate defect detection. Additionally, the use of advanced robotics in the inspection process has improved efficiency and reduced human error.

Thermomechanical Analyzer (TMA)

Thermomechanical Analyzer (TMA) is a crucial tool for evaluating material deformations under thermal or mechanical stress. It helps in measuring linear expansion coefficients and glass transition temperatures in PCB substrates. These measurements are essential for preventing metallized hole fractures that may occur post-soldering.

Having a good understanding of TMA and its analysis techniques is key to comprehending PCB failure mechanisms. This knowledge can greatly enhance quality control processes, allowing for the effective anticipation and prevention of future issues.