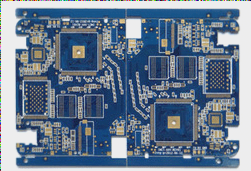

To achieve optimal performance in electronic circuits, the printed circuit board (PCB) serves as the foundation for circuit components and devices within electronic products. Even if the circuit schematic is designed correctly, improper PCB design can negatively impact the reliability of electronic products. When designing a PCB, it is crucial to apply appropriate methods, adhere to fundamental PCB design principles, and meet anti-interference design requirements. The arrangement of components and wiring layout is critical. To design high-quality, cost-effective PCBs, the following general principles should be observed:

**Layout**

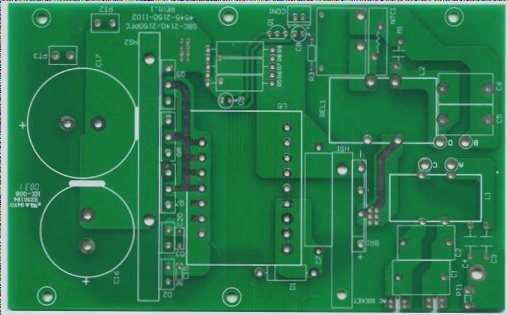

First, consider the size of the PCB. An excessively large PCB leads to longer printed traces, increased impedance, reduced noise immunity, and higher costs. Conversely, a PCB that is too small may result in poor heat dissipation and increased susceptibility to interference between adjacent traces. After determining the PCB size, the placement of special components should be established. Finally, layout all circuit components according to their functional units.

When determining the placement of special components, the following principles should be followed:

1. Minimize the distance between high-frequency components to reduce their distribution parameters and mutual electromagnetic interference. Components sensitive to interference should not be placed too close to each other, and input/output components should be positioned as far apart as possible.

2. Some components or wires may have significant potential differences. To prevent accidental short circuits due to discharge, increase the spacing between them. High-voltage components should be positioned in locations that are not easily accessible during debugging.

3. Components weighing over 15g should be secured with brackets before soldering. Large, heavy components that generate substantial heat should not be mounted on the PCB; instead, they should be installed on the chassis bottom plate of the entire machine, with thermal management in mind. Thermal components should be kept at a distance from heat-generating components.

4*When laying out adjustable components such as potentiometers, adjustable inductance coils, variable capacitors, and micro switches, it’s essential to consider the overall structural requirements of the entire device. If adjustments are made internally, these components should be positioned on the printed circuit board for convenient access; if adjustments are external, their placement must align with the adjustment knob on the chassis panel.

5*The positions for the positioning holes on the printed board and the fixed bracket must be accounted for.

When designing the PCB layout for circuit components, it is crucial to adhere to anti-interference design principles:

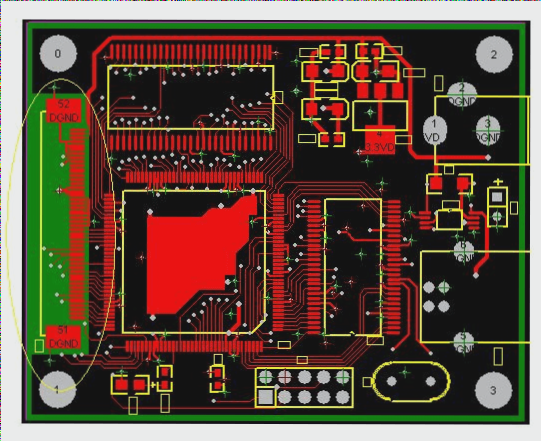

1* Organize each functional circuit unit according to the signal flow, ensuring the layout facilitates efficient signal circulation while maintaining a consistent signal direction as much as possible.

2* Use the core component of each functional circuit as a focal point and arrange other components around it. Components should be placed evenly, neatly, and compactly on the PCB, minimizing the length of leads and connections between them.

3* For circuits operating at high frequencies, the distribution parameters among components should be carefully considered. Ideally, components should be arranged in parallel to enhance aesthetics, simplify installation and soldering, and facilitate mass production.

4* Components positioned along the edge of the circuit board should maintain a distance of at least 2mm from the edge. The optimal shape for a circuit board is rectangular, with length-to-width ratios of 3:2 or 4:3. For boards larger than 200*150mm, mechanical strength considerations become important.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me

**Layout**

First, consider the size of the PCB. An excessively large PCB leads to longer printed traces, increased impedance, reduced noise immunity, and higher costs. Conversely, a PCB that is too small may result in poor heat dissipation and increased susceptibility to interference between adjacent traces. After determining the PCB size, the placement of special components should be established. Finally, layout all circuit components according to their functional units.

When determining the placement of special components, the following principles should be followed:

1. Minimize the distance between high-frequency components to reduce their distribution parameters and mutual electromagnetic interference. Components sensitive to interference should not be placed too close to each other, and input/output components should be positioned as far apart as possible.

2. Some components or wires may have significant potential differences. To prevent accidental short circuits due to discharge, increase the spacing between them. High-voltage components should be positioned in locations that are not easily accessible during debugging.

3. Components weighing over 15g should be secured with brackets before soldering. Large, heavy components that generate substantial heat should not be mounted on the PCB; instead, they should be installed on the chassis bottom plate of the entire machine, with thermal management in mind. Thermal components should be kept at a distance from heat-generating components.

4*When laying out adjustable components such as potentiometers, adjustable inductance coils, variable capacitors, and micro switches, it’s essential to consider the overall structural requirements of the entire device. If adjustments are made internally, these components should be positioned on the printed circuit board for convenient access; if adjustments are external, their placement must align with the adjustment knob on the chassis panel.

5*The positions for the positioning holes on the printed board and the fixed bracket must be accounted for.

When designing the PCB layout for circuit components, it is crucial to adhere to anti-interference design principles:

1* Organize each functional circuit unit according to the signal flow, ensuring the layout facilitates efficient signal circulation while maintaining a consistent signal direction as much as possible.

2* Use the core component of each functional circuit as a focal point and arrange other components around it. Components should be placed evenly, neatly, and compactly on the PCB, minimizing the length of leads and connections between them.

3* For circuits operating at high frequencies, the distribution parameters among components should be carefully considered. Ideally, components should be arranged in parallel to enhance aesthetics, simplify installation and soldering, and facilitate mass production.

4* Components positioned along the edge of the circuit board should maintain a distance of at least 2mm from the edge. The optimal shape for a circuit board is rectangular, with length-to-width ratios of 3:2 or 4:3. For boards larger than 200*150mm, mechanical strength considerations become important.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me