Lead-Free Environmental Protection in PCB Manufacturing

Lead-free environmental protection is a crucial topic in the PCB and PCBA manufacturing industry, posing technical challenges for manufacturers. WellCircuits, a leading player in the field, has been dedicated to enhancing PCB prototyping design. Here are some key advancements:

1. Enhanced Package Library Establishment

- Consideration of the impact of lead-free soldering temperature on device pad

- Conducting experiments to ensure optimal soldering temperature

2. Innovative Design Methods

- Focus on even heating of devices to prevent welding tombstones

- Development of specialized software for thermal balance

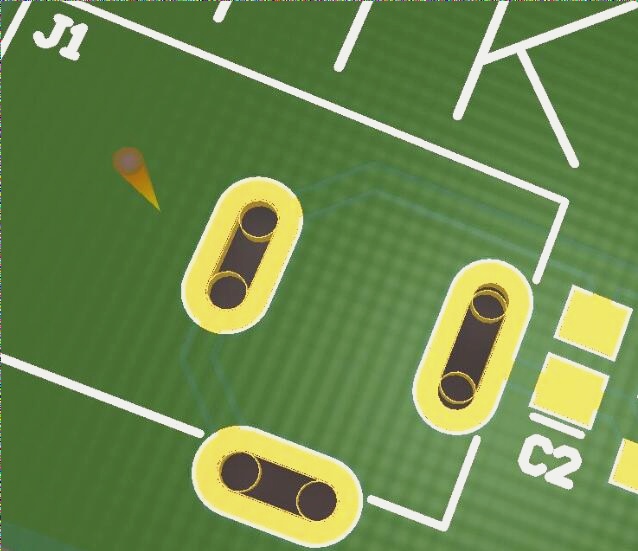

3. Surface Treatment Selection

- Adoption of different surface treatment methods based on product requirements

- Subtle differences in packaging or design with various treatment methods

4. Importance of Identification Description

- Addition of identification symbols on lead-free boards for easy processing

WellCircuits Limited specializes in producing high-precision circuit boards, including HDI, thick copper, backplanes, rigid-flex combinations, and more. Their products cater to diverse customer needs, ensuring quality and reliability in every project.