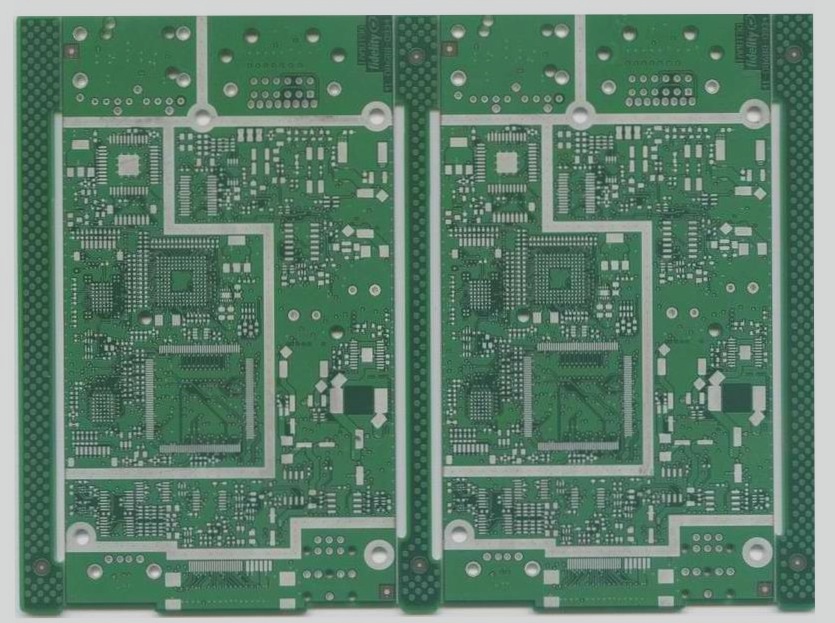

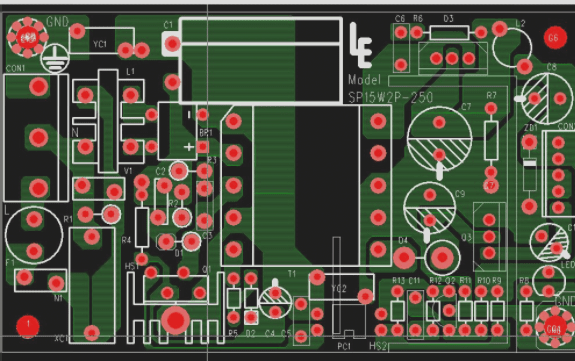

When considering the performance characteristics of the printed circuit board (PCB) substrate, it is crucial to take into account both mechanical and electrical properties, especially those pertinent to thermal cycling and soldering operations. These factors are paramount in the selection of standard products.

1. **CTE-Z Axis (Coefficient of Thermal Expansion):** This index measures the substrate’s expansion when subjected to heat. It is expressed in PPM/°C (before and after Tg) and as a percentage within a specified temperature range.

2. **Td (Decomposition Temperature):** This denotes the temperature at which the printed circuit board (PCB) material experiences a 5% weight change, determining its thermal stability.

3. **Tg (Glass Transition Temperature):** This marks the temperature at which a material transitions from a rigid to a plastic or softer state.

4. **T260 (Delamination Time):** The time required for the substrate to delaminate at 260°C.

5. **T288 (Delamination Time):** The time required for the substrate to delaminate at 288°C.

6. **Dk (Dielectric Constant):** This indicates the ratio of capacitance when using the material as a dielectric compared to a similar capacitor with a vacuum as its dielectric.

7. **CTI (Comparative Tracking Index):** This metric assesses the electrical breakdown characteristics of insulated PCB materials, crucial for evaluating electrical equipment safety.

As a professional manufacturer of flexible printed circuits (FPCs), WellCircuits Limited is honored to have collaborated with many clients. We are dedicated to assisting our new customers in every possible way. Please don’t hesitate to reach out to us with any inquiries.

1. **CTE-Z Axis (Coefficient of Thermal Expansion):** This index measures the substrate’s expansion when subjected to heat. It is expressed in PPM/°C (before and after Tg) and as a percentage within a specified temperature range.

2. **Td (Decomposition Temperature):** This denotes the temperature at which the printed circuit board (PCB) material experiences a 5% weight change, determining its thermal stability.

3. **Tg (Glass Transition Temperature):** This marks the temperature at which a material transitions from a rigid to a plastic or softer state.

4. **T260 (Delamination Time):** The time required for the substrate to delaminate at 260°C.

5. **T288 (Delamination Time):** The time required for the substrate to delaminate at 288°C.

6. **Dk (Dielectric Constant):** This indicates the ratio of capacitance when using the material as a dielectric compared to a similar capacitor with a vacuum as its dielectric.

7. **CTI (Comparative Tracking Index):** This metric assesses the electrical breakdown characteristics of insulated PCB materials, crucial for evaluating electrical equipment safety.

As a professional manufacturer of flexible printed circuits (FPCs), WellCircuits Limited is honored to have collaborated with many clients. We are dedicated to assisting our new customers in every possible way. Please don’t hesitate to reach out to us with any inquiries.