Key Tips for Creating Optimal CAD Models for Tabletop CNC Milling

Whether you are working with metal or plastic, preparing a Computer-Aided Design (CAD) drawing is the crucial first step toward achieving a flawless finish on your Tabletop Milling Machine. However, the path from concept to production is not as simple as just firing up your CNC mill when inspiration strikes. It demands meticulous planning and attention to detail to ensure precise and high-quality results.

Ensure Comprehensive Detailing Before Starting

Before diving into CAD modeling, take the time to develop a clear and comprehensive vision of your design concept. Create a detailed technical drawing covering critical features, dimensions, tolerances, and finishing preferences. Refine this drawing continuously until you are fully satisfied before transitioning it into a CAD model.

Optimize Your Design for Manufacturing Feasibility

When preparing your CAD model for CNC milling, consider design intricacies like cavities, edges, and wall thicknesses. Follow these best practices to optimize your model for manufacturability:

- Adjust cutting depths based on tool diameter to avoid inefficiencies.

- Increase corner radii for better finishes on internal corners.

- Utilize T-bone undercuts for right-angled internal corners.

- Maintain minimum wall thickness for material strength.

- Plan hole placements carefully for tight-tolerance holes.

- Avoid small thread sizes for better results.

Eliminate Redundancies for Smooth Manufacturing

Remove overlapping vectors in your CAD file to prevent material weakening and design flaws during manufacturing. Simplify your design by removing duplicates, consolidating lines, and ensuring consistency across the model.

Incorporating Text into Your Design

When including text in your design, maintain proper spacing between characters, choose clear fonts, and recess the text into the design for engraving or etching on the final product.

Continuous Practice Leads to Mastery

Mastering CAD modeling is an ongoing journey that requires dedication and practice. Invest time and effort in developing expertise, and be prepared for new challenges that will further enhance your skills.

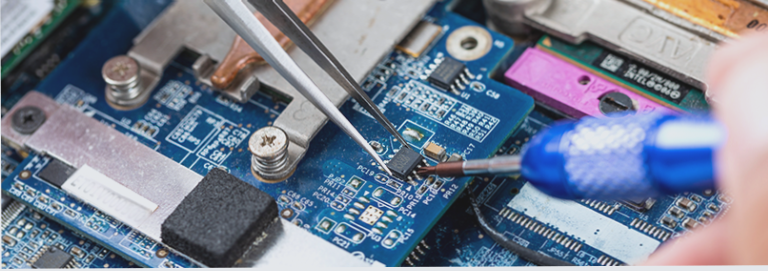

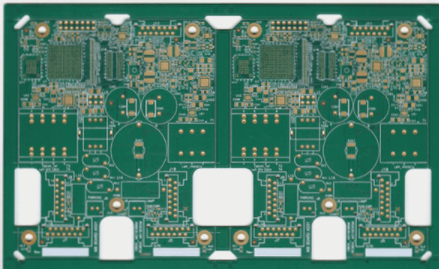

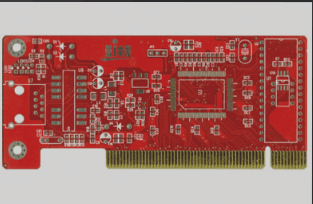

Embrace Lifelong Learning in PCB Expertise

Embark on a journey of continuous learning in the realm of PCB and PCBA. Dive into online tutorials, participate in vibrant forums, and actively seek feedback from your peers. By sharing your projects for constructive criticism, you can refine your skills and progress from a novice to a seasoned professional. This transformation will not only boost your confidence but also enhance your efficiency in the field!

Connect with Us for PCB and PCBA Queries

If you have any inquiries or doubts concerning PCB or PCBA, don’t hesitate to reach out to us at info@wellcircuits.com. We are here to provide you with expert guidance and support on all your circuit board needs.