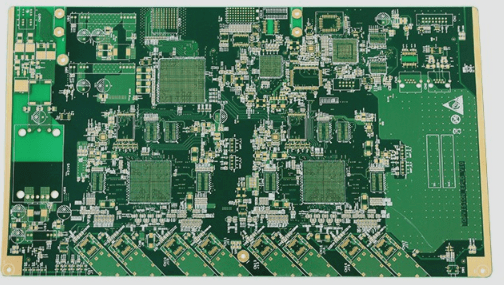

1. The following presents basic knowledge about PCB substrate materials:

2. The gold-plated process incurs the highest cost among all plating methods. However, it currently stands as the most stable and suitable option for lead-free processes. Particularly for high-unit price or high-reliability electronic products, the board serves as the fundamental material.

3. The OSP process boasts the lowest cost and ease of operation. Nonetheless, its implementation demands assembly plants to adjust equipment and process conditions, leading to poor reworkability. Consequently, its popularity remains limited. Employing this sheet material involves the destruction of the protective film pre-coated on the PAD after exposure to high temperatures, resulting in diminished solderability. This issue exacerbates during secondary reflow of the substrate. Therefore, if a DIP process is necessary, soldering challenges arise at the DIP end.

4. Despite silver’s high mobility, which can cause electric leakage, contemporary “immersion silver plating” isn’t solely metallic silver but includes “organic silver” co-plated with organic substances. This formulation meets the requirements of future lead-free processes, with a solderability lifespan surpassing that of OSP boards.

5. The primary concern with this substrate type is the “BlackPad” issue. Consequently, many major manufacturers resist adopting the lead-free process, although it remains prevalent among most manufacturers.

6. This substrate type is prone to contamination and scratching. Furthermore, the flux process induces oxidation and discoloration. Due to these drawbacks, most manufacturers refrain from utilizing this process, despite its relatively higher cost.

7. Due to its cost-effectiveness, excellent solderability, high reliability, and broad compatibility, the spray tin plate variant with robust soldering characteristics contains lead, rendering it incompatible with lead-free processes.

8. Another variant is the “tin-silver copper-sprayed tin plate.” However, due to its limited usage, obtaining characteristic data proves challenging.

2. The gold-plated process incurs the highest cost among all plating methods. However, it currently stands as the most stable and suitable option for lead-free processes. Particularly for high-unit price or high-reliability electronic products, the board serves as the fundamental material.

3. The OSP process boasts the lowest cost and ease of operation. Nonetheless, its implementation demands assembly plants to adjust equipment and process conditions, leading to poor reworkability. Consequently, its popularity remains limited. Employing this sheet material involves the destruction of the protective film pre-coated on the PAD after exposure to high temperatures, resulting in diminished solderability. This issue exacerbates during secondary reflow of the substrate. Therefore, if a DIP process is necessary, soldering challenges arise at the DIP end.

4. Despite silver’s high mobility, which can cause electric leakage, contemporary “immersion silver plating” isn’t solely metallic silver but includes “organic silver” co-plated with organic substances. This formulation meets the requirements of future lead-free processes, with a solderability lifespan surpassing that of OSP boards.

5. The primary concern with this substrate type is the “BlackPad” issue. Consequently, many major manufacturers resist adopting the lead-free process, although it remains prevalent among most manufacturers.

6. This substrate type is prone to contamination and scratching. Furthermore, the flux process induces oxidation and discoloration. Due to these drawbacks, most manufacturers refrain from utilizing this process, despite its relatively higher cost.

7. Due to its cost-effectiveness, excellent solderability, high reliability, and broad compatibility, the spray tin plate variant with robust soldering characteristics contains lead, rendering it incompatible with lead-free processes.

8. Another variant is the “tin-silver copper-sprayed tin plate.” However, due to its limited usage, obtaining characteristic data proves challenging.