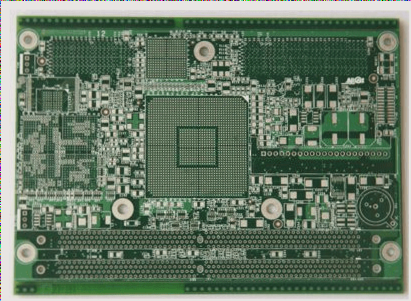

PCBA Production Equipment for Electronics Factories

-

Solder Paste Printer

Modern solder paste printers play a crucial role in PCBA production. They apply solder paste or adhesive onto circuit boards, facilitating automatic component placement.

-

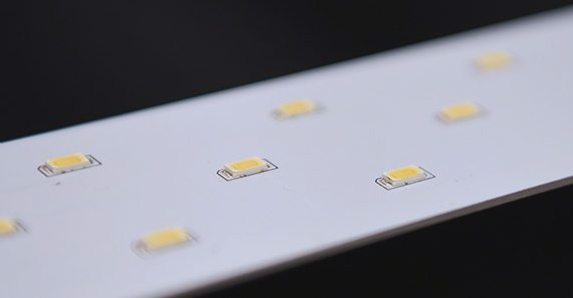

Mounting Machine (Surface Mount System)

The mounting machine accurately positions surface-mounted components onto PCB pads, coming in manual and automatic varieties.

-

Reflow Soldering

Reflow soldering utilizes heated air or nitrogen to melt solder, bonding components to the motherboard with advantages in temperature control and cost management.

-

Automatic Optical Inspection (AOI)

AOI uses optical principles to detect defects in soldering, rapidly advancing with manufacturers introducing their own inspection equipment.

-

Component Trimming Machines

These machines trim components efficiently in PCBA production.

-

Wave Soldering

Wave soldering is a common technique for soldering electronic components onto PCBs.

-

Tin Furnaces

Tin furnaces offer consistent welding quality and high efficiency in electronic soldering.

-

Washing Machines

Washing machines clean PCBA circuit boards effectively, removing contaminants and residues after soldering for enhanced reliability.

-

ICT Testing

ICT testing focuses on assessing PCBA circuits for open circuits, short circuits, and component soldering conditions.

In the PCBA circuit board production process, the quality and variety of machinery and equipment used are crucial for efficient assembly. The equipment range includes solder paste printers, mounting machines, reflow soldering ovens, AOI systems, component trimming machines, wave soldering machines, tin furnaces, washing machines, ICT fixtures, FCT fixtures, and aging test racks. The specific equipment in PCBA processing plants varies based on their size and production requirements.