We all understand that “no rules can make a circle,” and this principle applies to technology as well. What specifications should be considered in PCB design?

1. PCB Layout Design Specifications

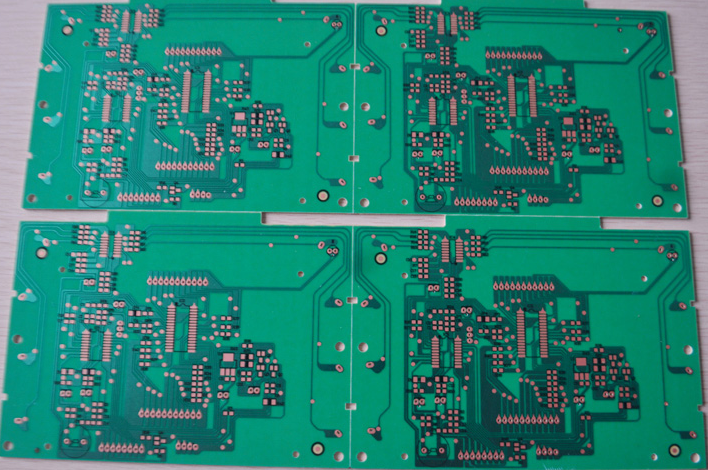

a. The distance from the board’s edge should be greater than 5mm (197mil).

b. Start by placing components closely related to the structure, such as connectors, switches, and power sockets.

c. Position core components and larger elements of the circuit function block first, then arrange surrounding circuit components around these core elements.

d. High-power components should be placed where they can effectively dissipate heat.

e. Larger components should not be centered on the board; instead, they should be positioned close to the fixed edge within the chassis.

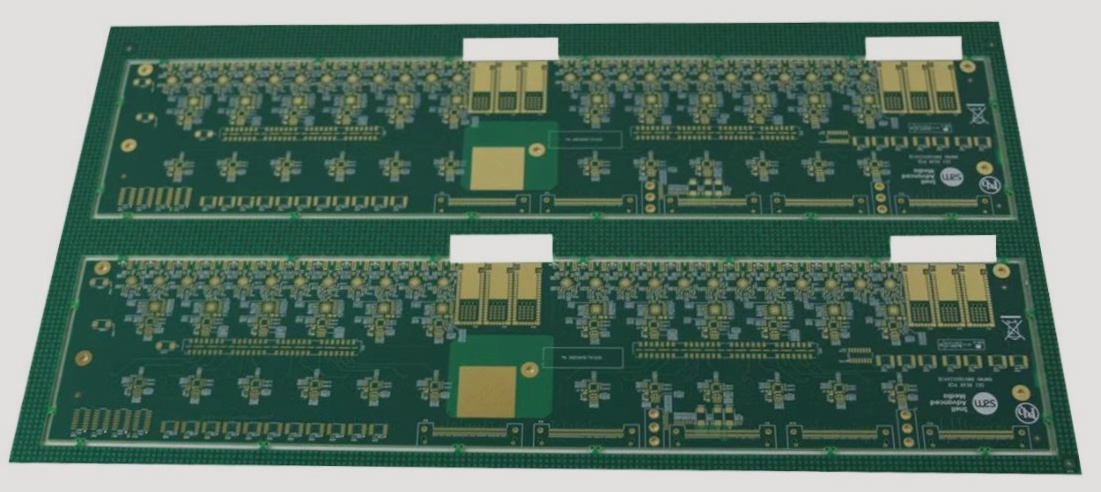

f. Components with high-frequency connections should be placed as close together as possible to minimize high-frequency signal distribution and electromagnetic interference.

g. Maintain a significant distance between input and output components.

h. High-voltage components should be positioned as far from hands as possible during debugging.

i. Thermal components must be kept away from heat-generating components.

j. The layout of adjustable components should allow for easy adjustments.

k. Consider the direction of signal flow and arrange the layout to keep this direction as consistent as possible.

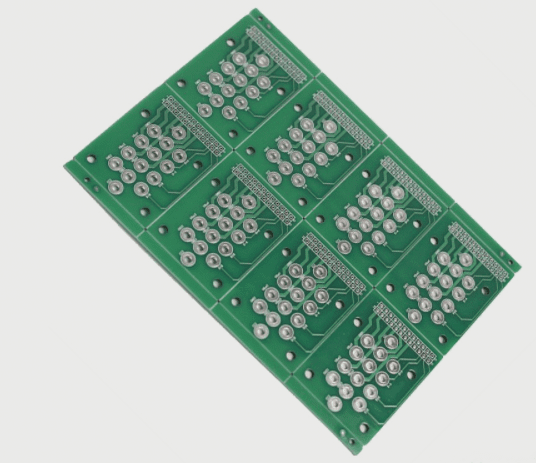

l. The layout should be uniform, tidy, and compact.

m. SMT components should align with the same pad orientation to facilitate assembly and soldering, reducing the chance of bridging.

n. Decoupling capacitors should be located near the power input.

o. The height of components on the wave soldering surface is limited to 4mm.

p. For PCBs with components on both sides, larger and denser ICs should be placed on the top layer, while the bottom layer should accommodate smaller components and patch components with fewer pins arranged loosely.

q. It is crucial to add heat sinks to small, high-heat components. Copper can be utilized to dissipate heat under high-power components, ensuring that no heat-sensitive components are nearby.

r. High-speed components should be placed as close to the connector as possible; digital and analog circuits should be separated, ideally by ground, which should connect at a single point.

s. The distance from the positioning hole to the nearest pad should be no less than 7.62mm (300mil), and the distance from the positioning hole to the edge of the surface mount device should be at least 5.08mm (200mil).

Sure! Here’s a polished version of your article while keeping the original structure:

2. PCB Wiring Specification Design

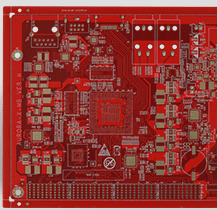

a. Avoid sharp angles in routing; instead, use right angles and forty-five-degree angles where possible.

b. Signal lines on adjacent layers should be routed orthogonally.

c. High-frequency signals should be kept as short as possible.

e. Minimize adjacent parallel routing for input and output signals; ideally, insert a ground wire between them to prevent feedback coupling.

f. For double-sided PCBs, the ground wire direction should align with the data flow to enhance noise immunity.

g. Digital ground and analog ground should be kept separate.

h. Clock and high-frequency signal lines should be designed with line widths that meet characteristic impedance requirements for effective impedance matching.

i. Ensure even hole distribution across the entire circuit board.

j. Separate power and ground layers, keeping power and ground lines as short and thick as feasible, minimizing the loop formed by the power supply and ground.

k. Clock routing should minimize the number of vias and avoid running parallel to other signal lines. Maintain distance from general signal lines to prevent interference; additionally, steer clear of power supply areas to avoid interaction between power and clock signals. When multiple clocks of different frequencies are present, do not run them side by side; keep clock lines away from output interfaces to prevent high-frequency clock coupling into output cables. If a dedicated clock generation chip is present, do not route any wires beneath it; copper should be laid instead, and if necessary, it should be specially cut out.

l. Differential signal pairs should generally be routed in parallel with minimal vias. When vias are necessary, they should be placed together to ensure impedance matching.

m. The distance between solder joints should be minimal, ensuring that they are not directly connected; vias from the mounting plate should be positioned as far from the pads as possible.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me