Ultra-High Speeds and Ground Plane Design in PCB Boards

As electronic applications increasingly rely on flex and rigid-flex PCB boards, achieving ultra-high speeds is crucial. These systems require ground planes to ensure effective isolation and separate RF and digital references within wireless protocols.

High speeds and frequencies bring about signal integrity challenges, many of which are related to the positioning and geometry of ground planes in a PCB.

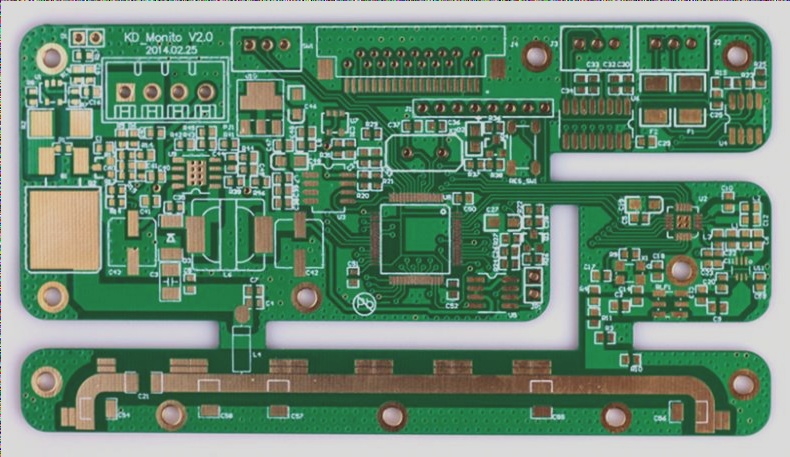

Grid Ground Plane Design

To maintain a reliable 0 V reference on flex and rigid-flex boards, a common approach is to implement a hatched or grid-like ground plane on the flex ribbon. This design offers substantial shielding over a broad frequency range while allowing flexibility for bending and folding.

Impedance Control

Implementing a meshed ground plane on rigid-flex or flex PCB boards enables consistent trace impedance and effective shielding. Different geometric parameters of the mesh plane structure can impact impedance control and flexibility.

Fiber Weave Effect

Grid ground planes on PCB boards can resemble the glass weave pattern in laminates, potentially causing fiber weave effects. These effects can lead to resonances in the mesh at specific frequencies, impacting signal transmission and radiation.

High Q Resonance

Meshes in the ground plane form resonant cavities with high Q values, resulting in lower losses and increased cavity emission. These resonances can enhance power losses and affect signal integrity in high-frequency applications.

Benefits of Mesh Ground Plane in PCB Design

A mesh ground plane plays a crucial role in ensuring that any radiated electromagnetic interference (EMI) from the fiber braid cavity is directed along the board’s edge. However, open cavities in the mesh can lead to reduced isolation and potential radiation along the surface of the flexible ribbon. This dual effect makes the trace more prone to radiating while increasing its vulnerability to external EMI.

To counter these challenges, utilizing a tighter mesh structure is recommended. This approach is akin to using a denser glass weave to counteract the fiber weave effect. By adopting these strategies, designers can enhance the performance and reliability of flexible and rigid-flex PCBs.

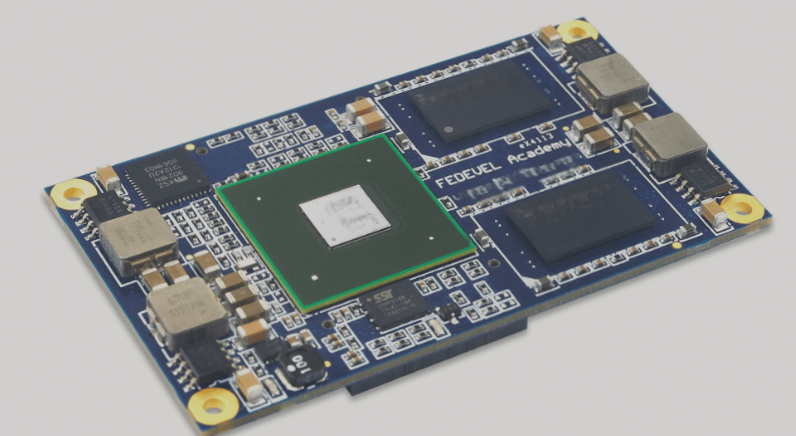

Future Trends in PCB Manufacturing

The field of flexible and rigid-flex PCBs is continuously advancing with the introduction of innovative manufacturing capabilities. As technology progresses, we can expect these PCB types to evolve further, offering enhanced functionalities and improved performance.