Computing devices and electronics are becoming more powerful and smaller simultaneously. A huge credit for this goes to the PCB technology. The PCB technology has evolved a lot over the years, and these days we have a BGA Chip in most PCBs instead of the traditional components. It is the technology we rapidly adapt to in most devices today.

However, being new is why most people lack basic knowledge about these chips. So, here we will discuss everything you need to know about the BGA Chips in PCB.

What is BGA technology?

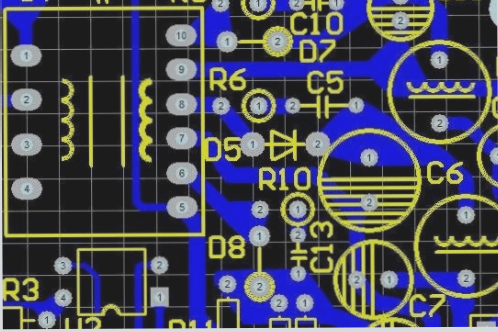

BGA stands for Ball Grid Array. It is a technology where IC chips have a grid array of solder balls on the underside. Similarly, there is a grid array of soldering points on the PCB. Here the array of balls of solder present on the underside of the integrated circuit chip is heated.

The solder balls melt and connect strongly with the solder pad array on the PCB. While it is commonly known as BGA, it is sometimes referred to as Chip Size Package(CSP).

A little about the history of BGA Chip

In the older days, the PCB chips were made thicker. Those were usually made on a single side with holes in the circuit. The components and IC chips had wires or pins passing through those holes with solder points on one side. However, with the advent of the BGA technology, there have been a lot of advancements in the PCB manufacturing and usability fields.

What is a BGA Chip in PCB?

A BGA Chip in a PCB is a chip that has no connection points coming out of it. There are no connections on any side or the top. Here this Chip sits on the PCB with its ball grid array connections on the bottom side of the Chip. Some common examples of this Chip are:

- Processing units.

- Wi-Fi Modules in mobile phones

- Touch Screen Controller IC

- Charger IC, etc.

What makes a BGA Chip technology good for most applications?

While the traditional and older PCB technologies were working fine, why do we need a Ball Grid Array Chip these days? The long list of benefits this chip type brings is a major reason for it. Here we will be elaborating on some of the best benefits of the Ball Grid Array Chip technology.

These benefits are why we use this type of Chip for most applications today.

- Small size

The size is the first benefit and one of the biggest distinguishing factors between the Ball Grid Array Chip and traditional PCB technology. These chips are about 20 times smaller in terms of area. It means that a lot less space on the PCB will provide functionality and performance that we were getting previously with 20 times more space.

In some performance-centric applications, this small size reduces the bus length bringing better performance figures.

- One side has all the contacts.

Since the advent of PCB and different components of the PCB, we have seen all types of components. IC chips have pins on 1, 2, 3, and 4 sides. Those chips and components were good enough for the purpose, but they were not that good at efficiently using PCB real estate.

On the other hand, the Ball Grid Array Chips have all the connection points on the bottom. So, a Ball Grid Array Chip only takes space equal to its size as no long pins or wires are coming out.

- Solid solder ball connections are more reliable and durable

Another thing about not having pins and wires coming out of the Chip is the better reliability. There is always a chance of short circuits when there are bare pins or wires. Similarly, any sort of a jerk to the PCB may result in breaking the wire or connection pin.

It may halt the whole PCB from performing as intended. The Ball Grid Array Chip only has ball connections. These are much shorter and bring higher durability. Devices made with these chips are more reliable and durable.

- Quicker soldering time

Whether we consider the soldering time on a small scale or large scale, the Ball Grid Array Chips always need less soldering time. Traditionally, we have to individually solder every pin or wire of the Chip on a PCB. With the BGA Chips, it becomes quicker.

You only have to put the Chip at the right spot and heat it with the right equipment. Every connection will be perfectly soldered on the PCB within a few seconds. It saves a lot of manufacturing and repairing time.

- There are no restrictions on the shape and size of balls.

An interesting thing about the BGA chips is that they do not have any restrictions about the shape or size of the balls. The balls of these chips are available in different sizes. It depends on the circuit requirements. While the ball is round, the Chip can have a square or circular solder points. It also depends on the design and circuit requirements. So, there are no restrictions whatsoever.

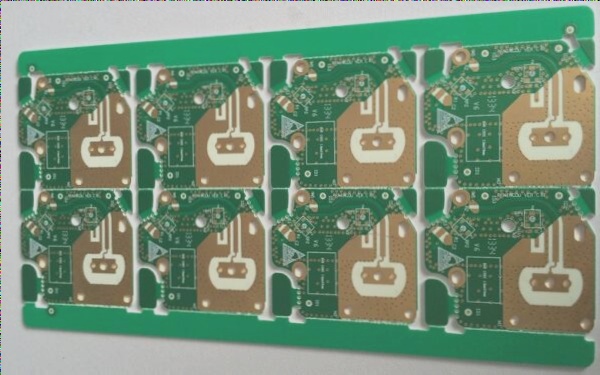

- Modern-day BGA Chips are stacked on top of one another

An amazing benefit of using the BGA Chips in the PCB world is the ability to stack them. The double-sided PCB printing was a revolutionary move in the history of PCBs. Now the ability to be stacked on top of one another from the BGA Chips is also bringing revolutionary benefits.

Some examples include whole double-layer motherboards stacked with BGA technology. Another example is the double-layer BGA chip processing unit of different smartphones.

Is there anything you need to be careful about?

The Ball Grid Array Chip technology might be the latest and bring many benefits. However, there are still some things that you must be very careful about. Here we will be discussing all of those things.

- The soldering process distributes heat.

The soldering process is the first thing you need to be careful about. BGA Chips need a hot air soldering station, and the air distributes heat wherever it goes. So, if there are any plastic or other components you do not want to affect, you need to protect them from the hot air. Otherwise, a simple soldering job can become complex.

- Higher temperatures for soldering

The soldering temperature is important to be careful about when dealing with BGA chips. Usually, you have to set your soldering station at 750 degrees Fahrenheit or 400 degrees Celsius. The hot gas coming out from the soldering station can be harmful to you and the nearby components. So, using the right protective equipment is always a good decision.

- Inspecting a component is not that simple and efficient

Say that you have a BGA chip that is faulty due to any reasons. You may have the schematic for that Chip, but inspecting that will not be that efficient. First of all, you have to study the whole circuit scheme. Secondly, tracking down the issue can be very time-consuming and complex with smaller chips and many balls.

Lastly, even when you track down the problem, you may be unable to repair the Chip. So, the ultimate solution for you will be replacing the whole Chip. Instead of wasting time checking the whole Chip, you can simply replace it once you are sure where the issue exists.

- It needs a thorough circuit development process.

All the amazing benefits of the Ball Grid Array Chip technology might be fascinating for you. However, before you make up your mind about making or using one, make it clear that it can only be used after a thorough circuit design process. In many cases, the BGA Chips and PCBs are made for one another and do not work with other parts.

- It can be costly for small-scale applications.

If you are planning to use BGA chips but are only planning to use them on a small scale, then it may be very costly compared to traditional circuit components. One Ball Grid Array Chip is also made for one specific circuit on a PCB. So, you may need to design and manufacture both.

What are the most common applications of a BGA Chip?

Considering all the things we discussed above, you may know how applicable these chips are in our daily life. Some common applications of the Ball Grid Array Chip in our daily life are:

- Components of Laptop and PC motherboards

- Smartphone and Tablet components

- Modern-day GPUs and Gaming Consoles

- Smartwatches, tech gadgets, etc.

BGA chips being this applicable include their small size, powerful internals, ease of replacing for repairing purposes and overall size-to-performance ratio.

Conclusion

In the older days, the PCBs used to be thicker and bigger while less powerful. However, these days most modern-day devices have a thinner footprint with stronger performance. It is because of the latest technology components based on BGA technology.

While it follows most of the traditional soldering and circuitry rules, there is much new about the BGA Chip. We hope that you know everything about this chip technology, including its benefits and things you need to be careful about.