PCB Assembly Technologies: Revolutionizing Industries, Military, and Space Exploration

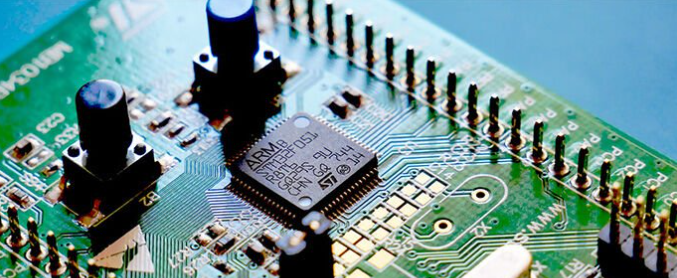

PCB assembly technologies play a crucial role in various sectors like industries, the military, and space exploration. Experts utilize a range of PCB assembly techniques to drive innovation and advancements worldwide. The integration of PCBs and diverse assembly methods is essential for the functioning of almost all electronic devices.

In the upcoming decades, the significance of these intricate circuit boards will only continue to grow, becoming indispensable in our daily lives.

Exploring Various Types of PCB Assembly

When it comes to PCB assembly, professionals employ diverse methodologies to integrate PCBs and electrical components onto a single board, creating intricate circuits capable of supplying varying levels of current to devices. Let’s delve into three primary types of PCB assembly, examining their features, benefits, and drawbacks.

Surface Mount Assembly Technology

Surface mount assembly, also known as SMT, stands out as a prevalent PCB assembly technique. In this method, printed boards are used to mount PCBs and other components, forming complete circuits. Manufacturers utilize solder paste to affix components to the board’s printed surface.

The Assembly Process

- Solder Paste Printing

For circuit creation, specialists prepare the board by printing solder paste using a solder paste printer. This step guides the circuit design, ensuring precise placement of components on the board.

- Picking and Placing Components

After applying solder paste to the board, the next step involves picking and placing components. Automated machinery meticulously mounts circuit elements, including PCBs, based on the solder paste guide, ensuring accurate component placement.

- Reflowing Solder

Once all components are correctly positioned, the circuit undergoes reflow soldering, subjecting it to high temperatures. This process melts the solder, creating secure joints between components and the board. Upon cooling, the circuit retains its structural integrity.

Advantages of Surface Mount Assembly

- Design Flexibility

Surface mount assembly offers design flexibility, allowing for customized circuit layouts based on specific requirements.

- Enhanced Stability

Through soldering paste, components establish robust connections, ensuring prolonged circuit stability and reliability.

- Automated Fabrication

Automation streamlines the assembly process, eliminating manual component mounting. Automated machines handle component placement with precision and efficiency.

PCB Assembly Technologies: A Comprehensive Guide

Surface Mount Assembly

Surface mount assembly offers exceptional performance in various conditions. Whether it’s extreme weather or harsh environments, this technology can withstand it all.

Cons of Surface Mount Assembly:

- Not as reliable due to paste print vulnerability over time.

- Small surface area for complex processes.

- Requires expertise for handling.

Applications of Surface Mount Assembly

- Widely used in medical devices.

- Commonly utilized in aerospace and defense systems.

Through-Hole Assembly Technology

Through-Hole assembly, dating back to the 1950s, remains a popular choice even with the rise of SMT in the 1980s.

The Process of Through-Hole Assembly:

- Manual placement of PCBA components using tools like tweezers.

- Quality inspection to ensure correct positioning, aided by automated systems.

- Wave soldering at high temperatures for reliable connections.

Advantages of Through-Hole Assembly:

- Reliable soldering for long-term use.

- Simple manual usability with well-spaced components.

- Durable soldering for longevity.

- Straightforward testing process.

Mixed PCB Assembly Technology: A Comprehensive Guide

Introduction

Testing the correct placement of components in PCBs is crucial. By aligning them with the transport frame, you can ensure accuracy.

Cons

- Not suitable for multilayered PCBs

While simple in composition and ideal for smaller PCBs, this technology may not be suitable for multilayered PCBs due to its limitations.

Applications

- Utilized in smartphones

- Commonly found in LED lights

Mixed PCB Assembly Technology Explained

Mixed PCB assembly technology combines SMT and THT methods, offering versatility in PCB development. Understanding the following conditions will enhance your knowledge:

Conditions

- Single-sided assembly

In single-sided mixed PCB assembly, primarily SMT is used with minimal THT assembly. This type is cost-effective due to the minimal use of Through-Hole PCB assembly.

- Double-sided assembly

Double-sided mixed PCB assembly can be done with or without adhesive. When adhesive is used, it requires multiple heating sessions for proper bonding.

- SMT on one side and THT on the other side

This type involves SMT on one side and THT on the other, requiring adhesives for connection. It combines the two basic PCB assembly technologies.

Pros

- Combines features of both SMT and THT PCB assemblies

- Offers different assembly options

- Testable by X-ray detection

Cons

- Soldering challenges

Adhesive in mixed PCB assembly can lead to soldering issues, affecting stability.

- Reduced efficiency

Due to additional heating processes required for adhesive bonding, the efficiency of mixed PCB assembly decreases.

- Higher cost

Adhesive usage in mixed PCB assembly adds to the overall cost of the process.

Applications

- Beneficial for video processing

- Commonly used in CPUs

- Found in smartphones and communication devices like computers, phones, and radar systems

- Utilized in LED lights and server boards

Conclusion

This guide provides insights into various types of PCB assembly technologies and their applications. Understanding these technologies will help you determine the best fit for your needs.