Printed Circuit Board Substrate Materials: The Key to Advanced Technology

Understanding PCB Substrate and Its Importance

- The substrate in a printed circuit board is crucial for durability and functionality.

- Engineers are constantly working to enhance technology in PCBs.

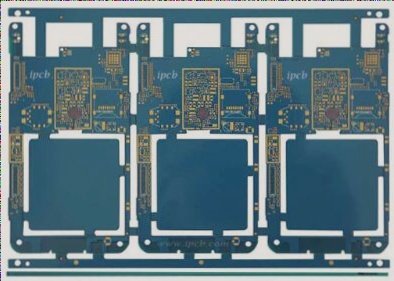

- Smart technologies like mobile phones rely on high-density PCB substrates.

Defining PCB Substrate Material

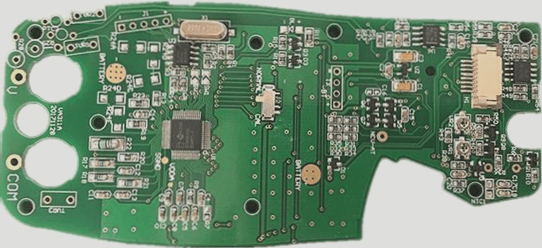

A PCB substrate is the physical substance that holds components together in a circuit board.

Choosing the right substrate is essential for the stability and structure of the PCB.

Key Characteristics of PCB Substrate

- Electrical Permittivity: Also known as dielectric constant, it determines the ability to store electrons in an electric field.

- Thermal Resistance: Responsible for heat transfer, impacting the efficiency of the material.

- CTE (Coefficient of Thermal Expansion): Affects the size of the material with temperature changes.

The Significance of PCB Substrate

Understanding the role of PCB substrate is crucial for the performance and reliability of electronic devices.

Choose the right substrate material to ensure the longevity and efficiency of your PCBs.

Advantages of Substrate-Like Printed Circuit Boards

Substrate-like printed circuit boards offer a solution for achieving a very thin spacing between components on electrical boards, requiring more advanced technology than traditional boards.

These boards are designed to meet the requirements for System-in-Package (SiP) packaging, allowing for the combination of various electronic parts with distinct features in a single system, enhancing functionality and ease of use.

Applications of Substrate-Like PCBs

Substrate-like printed circuit boards are commonly used in smartphones such as IOS and Android devices from companies like Apple and Samsung. The use of these boards is preferred due to their ease of handling compared to traditional PCBs.

Essentially, a substrate-like PCB is a material that significantly impacts the final product of the PCB, providing specific voltage and insulation properties.

- One key advantage of substrate-like PCBs is their ability to facilitate the development of advanced systems that integrate internet and Bluetooth connectivity seamlessly.

- With the rise of technologies like 5G and smart vehicles, there is a growing demand for smaller PCB sizes to enhance performance.

Substrate-like PCBs are now widely utilized to support these emerging technologies effectively.

Future Market Trends for Substrate-Like PCBs

The utilization of substrate-like printed circuit boards is expanding rapidly, positioning them as a leading-edge technology. Industry reports and experts indicate a broad scope for substrate-like PCBs in various consumer electronics, including smartphones, laptops, fitness devices, and more.

The increasing consumer demand for these products presents significant opportunities for the growth of the substrate-like PCB market.

- Substrate-like PCBs enable increased battery storage capacity in mobile devices by allowing thinner connections, leading to more efficient designs.

- By utilizing substrate-like PCBs, manufacturers can increase the number of layers while reducing overall width and distance by up to 30%, enhancing compactness.

Over the next five years, the market for smartphones and electronic gadgets is expected to expand further, driven by global internet penetration and increased smartphone usage. This growth will fuel the demand for substrate-like printed circuit boards.

Manufacturers are focusing on reducing the size of electronic devices to improve portability, driving the need for advanced substrate-like PCB models worldwide.

Considerations for Choosing a Substrate-Like PCB

Before selecting a substrate-like printed circuit board, several factors should be carefully evaluated to ensure optimal performance and compatibility with your requirements.

Tightness and Compactness

Key Considerations for Selecting a Printed Circuit Board Substrate

- Ensure the substrate is tightly bound to hold materials together effectively.

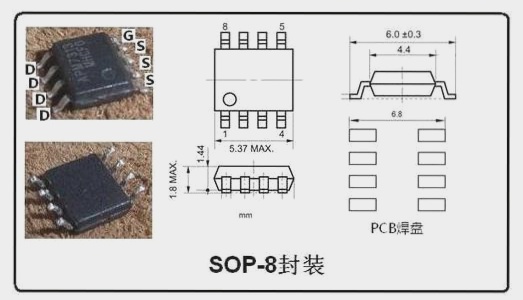

- Avoid using FR-4 substrates due to their unsuitability for higher frequencies.

- Opt for smooth copper foils to prevent frequency loss.

- Choose conductive foils that are ideal for conductivity and do not hinder circuit performance.

- Match the di-electric currents on the circuit board for smooth operation.

Avoid FR-4 Substrates

FR-4 substrates, while inexpensive and readily available, are not recommended by reputable companies for their unsuitable structure for higher frequencies.

Use Smooth Copper Foils

Opt for smooth copper foils to prevent the loss of higher frequencies on your printed circuit board.

Avoid Poor Conductors of Electricity

Choose conductive foils that do not impede circuit performance and ensure smooth conductivity.

Match Di-electric Currents

Ensure that di-electric currents on the circuit board are matched to maintain smooth operation and prevent potential issues.

Conclusion

Printed circuit board substrates play a crucial role in the electronic industry and offer a wide range of applications for the future.