Types and Quality Inspection of PCBs

PCBs are classified into single-sided, double-sided, and multi-layer types. They can also be categorized as flexible, rigid, or flex-rigid PCBs. Quality classification includes Class 1, Class 2, and the most complex Class 3, which undergoes rigorous inspection.

Inspection Standards

- Country-specific PCB standards

- Military PCB standards

- Industrial PCB standards like SJ/T10309

- Device supplier quality standards

- Requirements labeled on PCB design drawings

PCB Inspection Items

Basic quality inspection methods for all PCBs include visual, electrical performance, technological performance, and metalized via inspection.

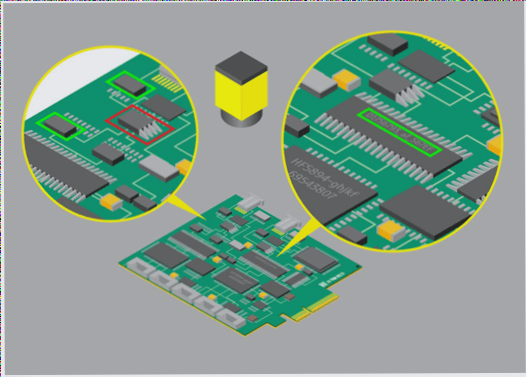

Visual Inspection

Visual inspection involves manual or automated checks for board thickness, surface roughness, warpage, assembly dimensions, conductive trace integrity, and more.

It also includes inspection of PCB surface quality, vias positions and diameters, pad plating quality, and coating.

Electrical Performance Inspection

Includes connecting performance tests using a multimeter and insulating performance tests to check the insulating resistor.

Technological Inspection involves checking solderability and plating adhesion. Metalized Via Inspection is crucial for ensuring the quality of PCBs.

The Importance of Metalized Vias in PCB Manufacturing

Ensuring the quality of metalized vias is crucial for the functionality and reliability of double or multi-layer PCBs. Issues often stem from poor via quality, underscoring the need for meticulous inspection processes. It is imperative that metalized vias exhibit smooth, complete walls without any empty holes or nodules.

The resistance variation during environmental testing should fall within the range of 5-10%. Additionally, assessing the adhesive strength between the metalized via and pad is essential. Metallographic analysis tests are conducted to evaluate plating plane quality, thickness, uniformity, and adhesive strength, encompassing both visual and mechanical inspections.

Inspection of Multi-layered PCBs

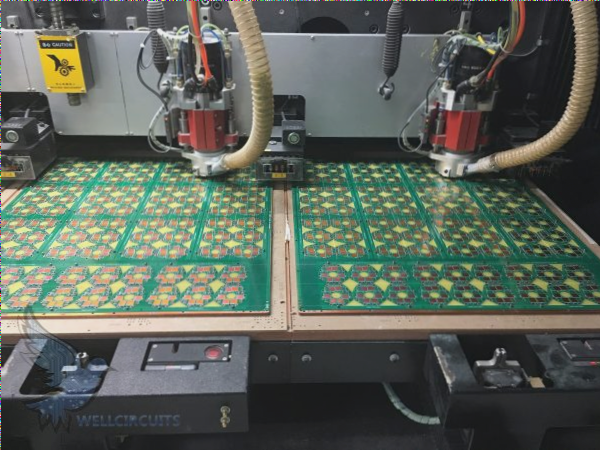

Multi-layered PCBs present heightened complexity, making it challenging to pinpoint and address potential breakdowns. Consequently, their inspection protocols are equally stringent. Various parameters, such as the resistance of conducting materials and metalized vias, short and open circuits within layers, insulation resistance of traces, adhesive strength between plates, anti-heat shock capabilities, and mechanical shock resistance, are scrutinized.

Advanced equipment and technology are employed to assess each parameter meticulously, ensuring the production of high-quality final PCBs.