Exciting News: Wellcircuits’ New Factory in Production!

Wellcircuits is thrilled to announce that our new factory is currently undergoing production testing and is set to commence formal production on March 16th. This development comes after an investment of $2,000,000 in state-of-the-art equipment at the beginning of 2018.

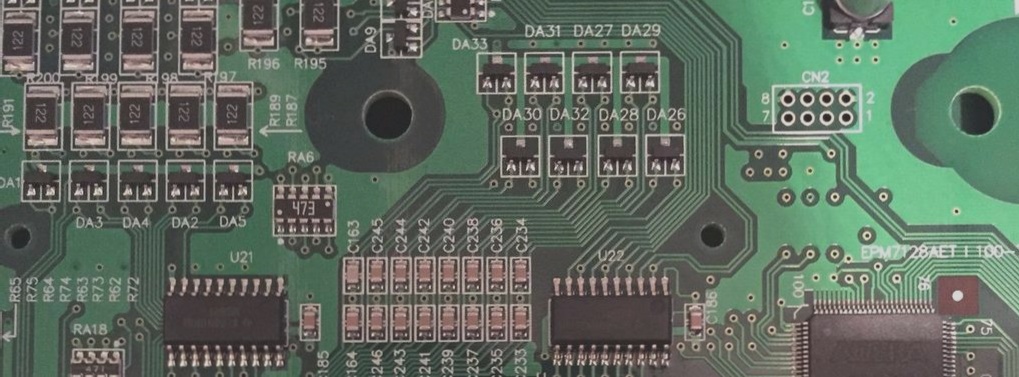

The recently acquired Surface Treatment Equipment and Automatic Copper Production Line are designed to cater to the increasing demand for PCBs both locally and internationally, ensuring timely delivery to our valued customers.

The new equipment comprises a blend of hardware and software components crucial for tasks like copper plating and plastic slag elimination. Its integration into our processes is expected to drive efficiency, boost production capacity, and shorten lead times significantly.

Key Machines at Wellcircuits:

- 6-axis Drilling Machine

- Automatic Professional Testing Machine

- Screw High-speed Flying Probe Testing Machine

- Automatic Laminator

- Exposure Machine

- Milling Machine

- Etching and Development Equipment

- Laminating Equipment

- AOI Line Detection Machine

- Laser Silkscreen Printer

Reach Out to Us!

If you have any inquiries regarding PCBs or PCBA, don’t hesitate to get in touch with us at info@wellcircuits.com.