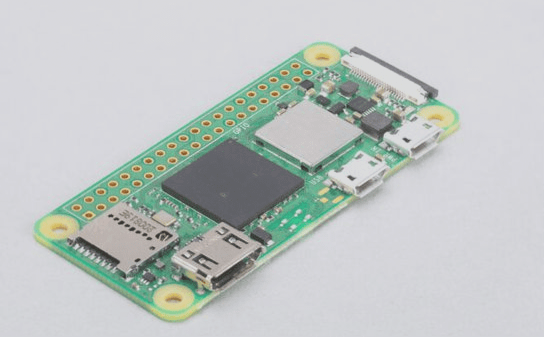

Enhancing PCB Performance with Copper Filling and Brass Coatings

In PCB design, copper areas are strategically filled with semi-fluid brass to optimize performance. This technique, known as “copper filling,” improves electrical and mechanical characteristics by reducing ball resistance, enhancing EMI resistance, and optimizing resource utilization. Brass coatings also aid in minimizing voltage drop and improving the power distribution system efficiency.

Managing Ground Connections with Brass Coatings

When dealing with different ground connections in a PCB (e.g., SGND, AGND, GND), brass coatings play a crucial role in protecting critical ground areas. By ensuring stable and low-resistance paths, brass coatings help prevent interference between various ground types. Proper PCB layout rules, including the strategic placement of the PCB counter, are essential for effective ground connection management.

Optimizing Copper Region Separation for Improved Performance

Careful management of the separation between copper regions like power and ground is vital to avoid crosstalk and short circuits. Designers often incorporate additional shielding copper layers, especially in high-frequency designs, to enhance shielding and power integrity. This shielding isolates sensitive components, ensuring reliable operation under different conditions, such as V50V, V36V, and V33V power supply circuits.

Creating a Co-Frequency Structure for Efficient Operation

The use of copper filling and strategic brass coatings is essential for enhancing PCB performance. By creating a co-frequency structure that optimizes power and signal integrity, PCBs can operate efficiently even in complex electronic systems.

Overview of Masking Brass in PCB Design: Key Considerations and Practical Insights

When incorporating brass masking in PCB designs, it is crucial to address grounding and EMI shielding effectively. This article explores single-point and dual-element connections, challenges in brass shielding, and best practices for heat dissipation and signal integrity optimization.

Grounding and Shielding: Single-Point vs. Dual-Element Connections

Two primary grounding types to consider with brass masking are single-element and dual-element grounding.

- Single-Element Grounding: Involves a direct link between signal ground and chassis ground, ensuring a simple connection for components like crystal oscillators.

- Dual-Element Grounding: Grounds the copper layer before and after the oscillator to achieve complete shielding and proper handling of return currents to prevent EMI.

Separate grounding of the crystal oscillator optimizes performance and minimizes interference, maintaining stable grounding for the system.

Challenges with Brass Shielding and Wave Soldering

While brass is effective for shielding copper in PCB designs, challenges like wave soldering issues and thermal dissipation need to be addressed.

- Wave Soldering Issues: Incorrect wave soldering can lead to problems like board warping or blistering, especially in larger boards.

- Thermal Dissipation: Proper management of brass shielding is crucial to prevent localized hot spots and ensure even heat distribution across the PCB.

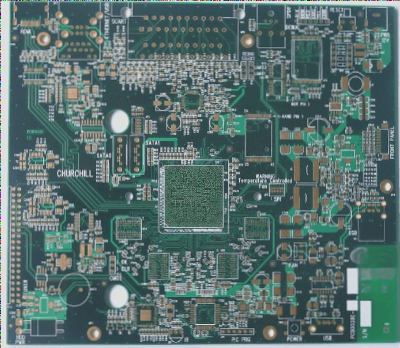

Designing with PCB Grids and Copper Layers for Shielding

Achieving Optimal PCB Design with Brass Shielding

When it comes to designing PCBs with brass shielding, one crucial aspect to consider is the grid structure. The effectiveness of the shielding largely depends on a flawless and uniform grid that covers both the brass components and the surrounding areas.

Grid-Powered Power Generation

In certain PCB designs, a grid structure plays a vital role in connecting power generation networks. By incorporating copper paving into the grid, the stability and shielding of the power network against external electromagnetic interference (EMI) are enhanced.

The Significance of Brass in Digital Circuits

Integrating brass into digital circuits is essential for reducing the impedance of the ground return path. This reduction is critical for maintaining signal integrity and minimizing noise interference. The process typically involves applying brass in specific steps:

- Initiating the application of brass at the main processor module, also known as the circuit’s “brain.”

- Interconnecting copper layers using wire coils or traces post the brass application to decrease magnetic interference within the circuit.

This combination of brass grounding and copper interconnections helps in minimizing signal interference and ensures stable circuit operation.

Simulated Circuit and Mixed-Signal Design Considerations

PCB designs often incorporate mixed-signal circuits that blend analog and digital components. Challenges arise in preventing interference between these signals, especially with sensitive components.

- Grounding Requirements for Mixed Circuits: Implementing single-point grounding is crucial to prevent digital noise from affecting analog signals, ensuring each signal has a clean return path.

- Signal Integrity: The PCB layout should minimize signal reflection and crosstalk between analog and digital channels. Careful treatment of the analog ground plane and dedicated shielding for the analog circuit are essential to contain noise effectively.

Conclusion: Effective PCB Design Practices with Brass Shielding

For PCB designs incorporating brass masking for EMI shielding, a systematic approach to grounding, shielding, and signal integrity is key.

- Utilize both single-element and dual-element grounding configurations to reduce impedance and noise.

- Exercise caution during wave soldering to prevent damage to the brass shielding and mitigate thermal concerns.

- Employ grid-based shielding and copper layers for uniform thermal dissipation and EMI protection.

- Implement grounding techniques tailored for mixed-signal circuits to prevent interference between analog and digital elements.

By adhering to these best practices, a well-shielded, high-performance PCB design can be achieved, resilient against noise and thermal challenges, ensuring reliable operation in demanding scenarios.