Designing High-Quality Medical PCBs: Essential Guidelines

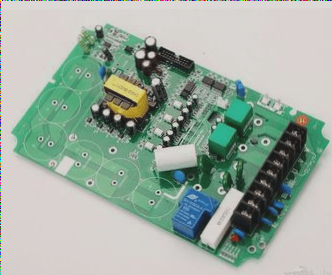

Introduction to Medical-Grade PCB Design

- Printed circuit boards (PCBs) play a vital role in various industries, including the medical sector.

- Medical-grade PCBs require precision and accuracy to meet industry standards.

- Regulations like Section 201(H) of the FD&C Act govern medical-grade PCB design.

Key Considerations in Medical PCB Design

- Focus on easy assembly and maintenance for efficient equipment performance.

- High-density interconnected PCBs are essential for accurate diagnosis and complex operations.

- Rigid-flex PCBs combine rigidity and flexibility, ideal for compact spaces.

Compliance with Medical PCB Standards

- Adherence to regulations like FCC Title 47 and US FDA 21 CFR Part 807 is crucial.

- Standards such as IEC 60601-1 and ISO 13485 ensure performance and safety.

Guidelines for Designing Compliant Medical PCBs

- Thorough understanding of regulations is necessary to design compliant PCBs.

- Avoid uncertain components and follow electronics best practices to minimize risks.

Importance of PCB Materials in the Medical Industry

- Strict requirements for PCB materials are essential for medical equipment reliability.

- Various PCB manufacturing options cater to different medical needs.

Distinguishing Medical-Grade PCBs

- Medical PCBs come in standard shapes like rectangular or circular, with custom options available.

For more information on designing high-quality medical PCBs, visit Wellcircuits.

Choosing the Right Substrate for Medical-Grade PCB Design

- RoHS Compliance

- High-Speed Digital Conversion

- High-Frequency Radio Frequency

- Temperature Considerations

- Coating and Cladding

Industry-Standard PCB Substrates

Copper Core, RO4003C, and domestic Shengyi PI are commonly used substrates in medical-grade PCB design.

High-Density Interconnect Boards (HDI)

HDI boards have more circuit connections than traditional boards, with micro-vias having diameters less than 0.006 inches.

Advantages of HDI in Medical-Grade PCBs

HDI boards offer shape and design efficiency, crucial for medical applications.

Glass Transition Temperature (TG)

Understanding TG is essential, as it determines the material’s performance and resistance to heat, humidity, and chemicals in medical-grade PCBs.

Quality Working Environment

Manufacturers must adhere to specific standards to ensure product quality and reliability in medical devices.

Choosing a Reliable Manufacturer

When selecting a PCB manufacturer, prioritize accuracy, adherence to standards, and compliance with medical device regulations.

Questions for Potential Manufacturers

- How long have you been in the PCB manufacturing business?

- Do you have experience producing motherboards for medical device companies?

- Can you guarantee the authenticity of components used?

- What quality assurance practices do you follow?

- What is your manufacturing test method for ensuring PCB quality and compliance?

- Is your company ISO 9001 certified?