PCB Proofing: Essential Parameters and Instructions

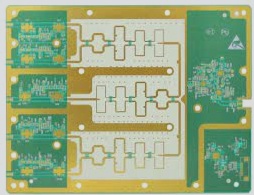

- Material: Specify the required material type, with FR4 (epoxy resin and woven fiberglass cloth) being the most common choice.

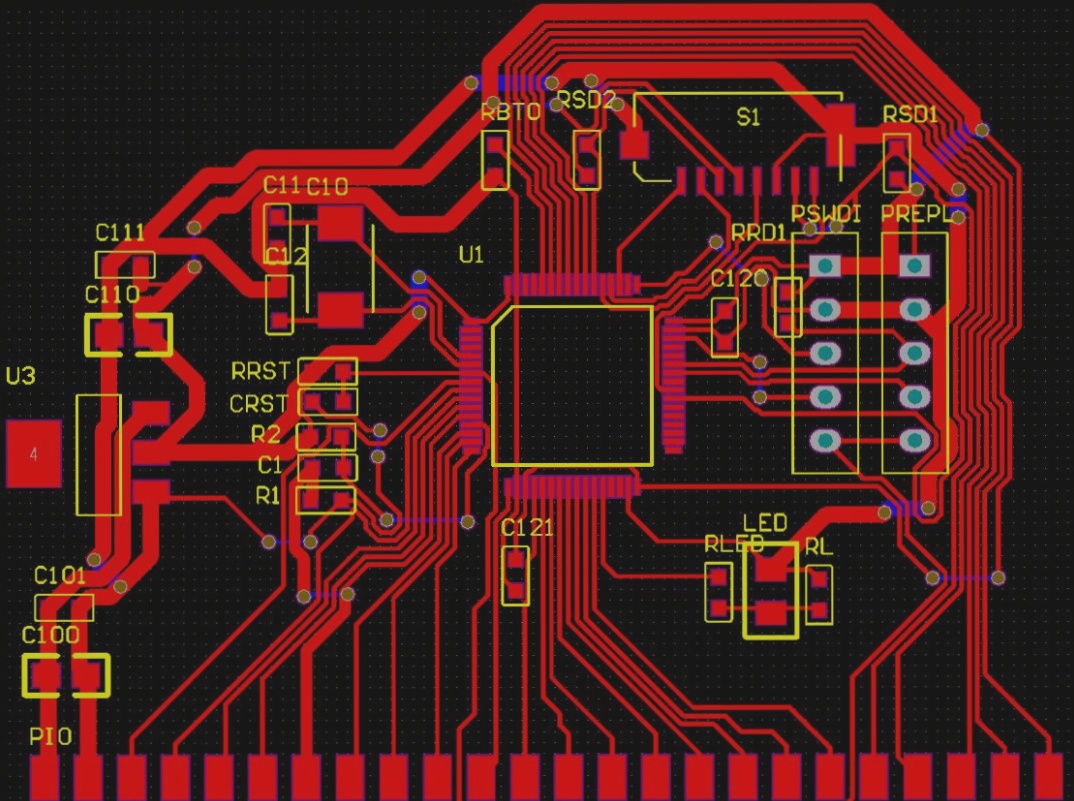

- Board Layer: Indicate the number of layers, impacting price and complexity.

- Solder Mask Color: Select from various colors, typically green.

- Silkscreen Color: Usually white for font and border colors.

- Copper Thickness: Balance thickness based on circuit current for cost-effectiveness.

- Via Solder Mask: Specify if the via should be insulated or left uninsulated.

- Surface Coating: Options include spray tin and gold plating.

- Quantity: Clearly state the required production quantity.

Understanding PCB Proofing

PCB proofing involves sending an engineer’s layout design to a manufacturer for trial production. With the rapid evolution of electronic products, the demand for PCB proofing is increasing, especially for multi-layer PCBs.

User Groups for PCB Proofing

Primarily catering to electronic engineers, PCB proofing services also benefit students, research institutes, and other professionals involved in academic research and product development.

Choosing the Right PCB Proofing Manufacturer