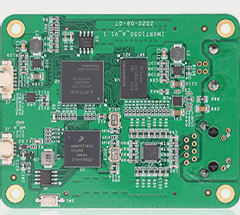

The Importance of Copper Clad Laminate (CCL) in PCB Manufacturing

Copper Clad Laminate (CCL) plays a crucial role in the production of printed circuit boards (PCBs) by providing the necessary substrate for conduction, insulation, and mechanical support. It represents a significant portion of the total manufacturing cost, emphasizing its importance in the PCB production process.

Key Functions of Copper Clad Laminate

- Facilitates interconnection and electrical insulation

- Supports the structural integrity of the PCB

- Influences electrical characteristics like signal transmission speed and energy loss

The properties of the copper clad laminate directly impact the overall performance, quality, and reliability of the PCB. Factors such as electrical characteristics, mechanical strength, and thermal stability are crucial in ensuring the effectiveness of the final product.

Choosing the right copper clad laminate is essential for optimizing PCB design and functionality, particularly in advanced electronic applications where performance and reliability are paramount.

Classification of Copper Clad Laminates

Copper Clad Laminates (CCL) are classified based on various properties to meet diverse application requirements:

Mechanical Rigidity

- Rigid Copper Clad Laminate: Solid and inflexible, suitable for traditional PCB designs

- Flexible Copper Clad Laminate: Designed for flexibility in applications like consumer electronics

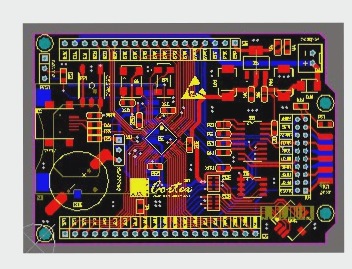

Insulating Material and Structure

- Organic Resin-based CCL: Widely used with materials like epoxy or phenolic for insulation

- Metal-based CCL: Incorporates metal substrates for better thermal management

- Ceramic-based CCL: Utilizes ceramic materials for superior heat dissipation in high-performance applications

Thickness of Copper Clad Laminate

- Thick Plates: Common in high-density interconnect (HDI) boards and power electronics

- Thin Plates: Ideal for space-constrained applications like mobile devices

Reinforcing Material

- Glass Cloth-based CCL: Known for strength, stability, and excellent electrical properties

- Paper-based CCL: Economical choice for less demanding applications

- Composite-based CCL (CME-1, CME-2): Tailored performance for specific applications

Flame Retardancy

CCLs are classified based on flame-retardant properties to ensure safety and compliance in PCB manufacturing according to UL standards (e.g., UL94, UL746E).

Flame Resistance Levels in PCB Materials

- UL-94V0, UL-94V1, UL-94V2, UL-94HB: These classifications represent different levels of flame resistance in PCB materials, with V0 offering the highest level of resistance.

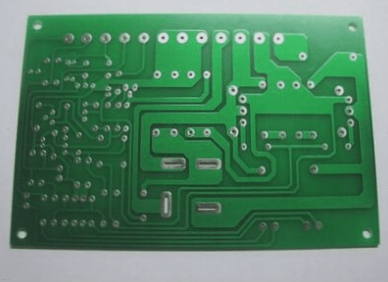

Key Quality Indicators for Copper Clad Laminates

The quality of Copper Clad Laminates plays a crucial role in determining the performance and reliability of the PCBs they support. Understanding the following quality indicators is essential:

- Peel Strength: Peel strength measures the force required to peel the copper foil from the substrate, indicating the bond strength crucial for durability under mechanical stresses and thermal cycling.

- Warpage: Warpage refers to the distortion of the laminate under external forces, affecting component alignment and manufacturing processes.

- Bending Strength: This index determines the laminate’s ability to withstand bending without damage, crucial for mechanical stress resilience.

- Dip Solder Resistance: Assessing how well the copper foil resists peeling during solder immersion is vital for reliability under high-temperature conditions.

Other technical indicators critical for PCB applications include:

- Surface Smoothness: Essential for consistent electrical performance and component mounting.

- Pit Depth: The presence of pits or voids can impact the copper foil’s integrity and electrical properties.

- Dielectric Properties: Factors like dielectric constant and dissipation factor influence signal integrity, especially in high-frequency scenarios.

- Surface Resistance: Low resistance ensures efficient electrical conduction and prevents resistive heating.

- Cyanide Resistance: Resistance to cyanide-based solutions during manufacturing processes is crucial for longevity and reliability.

Choosing the right Copper Clad Laminate involves considering mechanical, electrical, and thermal requirements, along with adherence to safety standards like flame retardancy. Meeting quality indicators is key to achieving high-performance, reliable PCBs across various applications.