Precision Fine Wire Creation with Semi-Additive Method

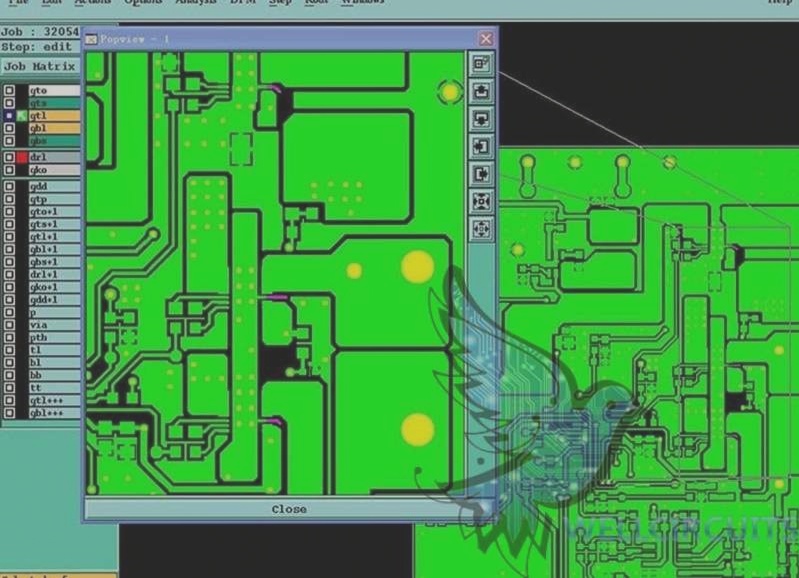

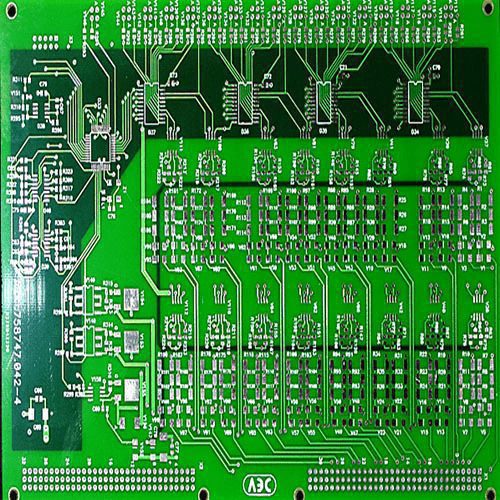

The semi-additive method involves depositing electroless copper on the entire board, followed by processes like applying dry film, exposure, and development. Electroplating is then used to create lines and holes, and the dry film is removed for stenciling. This technique enables the production of finer and smaller pitch lines, with benefits in reducing side etching during the stenciling process.

Key Techniques for Mastery

- Electroless Thick Copper Technology:

- Requires copper thickness greater than 0.05mil.

- Proper selection of copper sinking liquid for optimal outcomes.

- Graphic Plating Technology:

- Essential for semi-additive processes.

- Addresses issues with uneven current distribution during pattern plating.

- Utilizes forward and reverse pulse electroplating power supply for even coating distribution.

Blind Hole Filling via Electroplating

Traditional HDI laser blind via processes face challenges like voids and air entrapment. Conventional methods involve resin filling, but with reliability concerns. Adopting electroplating for blind hole filling, using electroplated copper, significantly improves reliability and process adaptability for intricate designs.

Enhancing HDI Process Capabilities

- Electroplated blind hole filling enhances reliability.

- Enables intricate circuit patterns and stacking of blind vias.

- Addresses complexities and flexibility requirements in design.