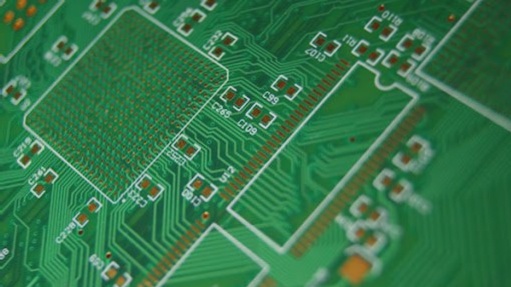

Factors Affecting PCB Steel Mesh Quality

- Production Process: Opt for electropolishing after laser cutting for best results. Avoid errors from chemical etching and electroforming processes.

- Materials Used: Choose quality materials like polyester mesh for screen frames and 304 steel sheet for better outcomes.

- Opening Design: Design openings carefully considering width to thickness ratio and area ratio for optimal stencil quality.

- Production Data: Ensure completeness of production data for better stencil quality.

- How to Use: Correct printing methods are crucial to prevent damage to the stencil.

- Cleaning: Promptly clean the stencil to prevent blockages in openings.

- Storage: Store steel mesh properly to avoid accidental damage and bending of the screen frame.

For the latest information on PCB fabrication, visit Wellcircuits.