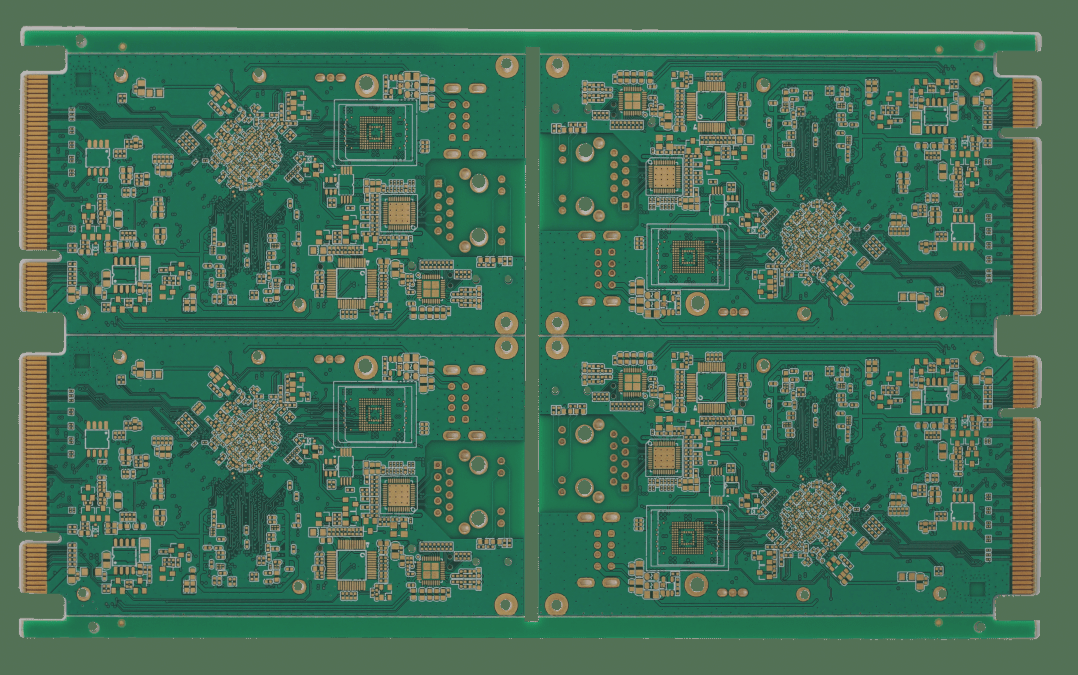

Under the competitive pressures of the professional circuit board market, numerous circuit board factories have resorted to various measures to reduce costs on raw materials and equipment, aiming to trim operating expenses. Unfortunately, this pursuit often comes at the expense of the quality of the circuit board products they produce. Below, the editors of WellCircuits will elucidate the factors contributing to the subpar quality of PCB circuit board products.

1. Circuit board production equipment falls short of standards:

Advancements in science and technology propel the rapid evolution of circuit board production equipment, accompanied by escalating prices. High-quality equipment forms the cornerstone of product excellence, necessitating significant investment to ensure efficiency and stability. Regrettably, many small circuit board factories find themselves unable to afford such costly equipment, resulting in compromised PCB proofing product quality.

2. Substandard quality of circuit board raw materials:

The quality of PCB raw materials constitutes the bedrock of multilayer circuit board excellence. Inferior materials yield circuit boards prone to blistering, delamination, warping, and uneven thickness, compromising overall product quality.

3. Inadequate circuit board production processes:

Each stage of circuit board production demands meticulous adherence to stringent processes, bolstered by appropriate testing equipment. These process parameters and equipment are pivotal in upholding circuit board quality stability. However, due to substandard production techniques, many circuit board manufacturers opt to compete solely on price, detrimentally affecting the quality of their output.

As a reputable FPC soft board manufacturer, WellCircuits Limited takes immense pride in our collaborations with esteemed partners like yourself. At WellCircuits Limited, we stand ever-ready to support our new customers in every possible manner. Should you have any queries, please do not hesitate to reach out to us at your convenience.

1. Circuit board production equipment falls short of standards:

Advancements in science and technology propel the rapid evolution of circuit board production equipment, accompanied by escalating prices. High-quality equipment forms the cornerstone of product excellence, necessitating significant investment to ensure efficiency and stability. Regrettably, many small circuit board factories find themselves unable to afford such costly equipment, resulting in compromised PCB proofing product quality.

2. Substandard quality of circuit board raw materials:

The quality of PCB raw materials constitutes the bedrock of multilayer circuit board excellence. Inferior materials yield circuit boards prone to blistering, delamination, warping, and uneven thickness, compromising overall product quality.

3. Inadequate circuit board production processes:

Each stage of circuit board production demands meticulous adherence to stringent processes, bolstered by appropriate testing equipment. These process parameters and equipment are pivotal in upholding circuit board quality stability. However, due to substandard production techniques, many circuit board manufacturers opt to compete solely on price, detrimentally affecting the quality of their output.

As a reputable FPC soft board manufacturer, WellCircuits Limited takes immense pride in our collaborations with esteemed partners like yourself. At WellCircuits Limited, we stand ever-ready to support our new customers in every possible manner. Should you have any queries, please do not hesitate to reach out to us at your convenience.