### Causes of PCB Board Bending and Warping and Prevention Methods

1. In the PCB manufacturing process, many circuit boards are susceptible to bending and warping during the Reflow stage. In severe cases, this can lead to issues such as incomplete soldering and tombstoning. How can we address this?

2. The causes of board bending and warping can vary for each board, but they ultimately stem from stress on the board exceeding the material’s tolerance. When the board experiences uneven stress, or when different areas of the board have varying capacities to withstand stress, bending and warping can occur.

3. So, where does this stress originate? The primary source of stress during the Reflow process is temperature. Heat not only softens the circuit board but also leads to distortion. Additionally, the material properties associated with thermal expansion and contraction contribute significantly to the bending issue.

4. Why do some boards exhibit different levels of bending and warping?

Before delving into the issues of board bending and warping, I recommend you review this article that analyzes the root causes and prevention strategies for PCB explosions. Some content will be relevant.

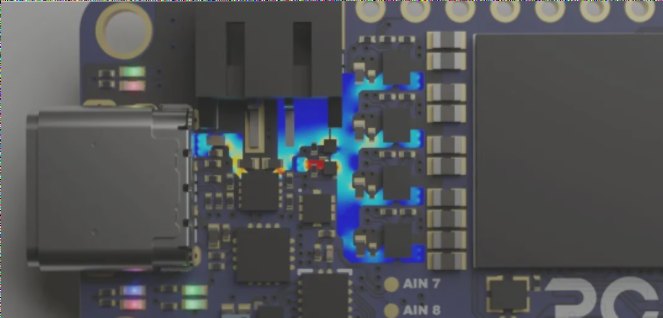

1. The uneven copper surface area on the circuit board can exacerbate bending and warping. Typically, large copper foil areas are included for grounding, and sometimes for the Vcc layer as well. If these copper foils are not evenly distributed across the board, it leads to uneven heat absorption and dissipation. Consequently, the board will expand and contract with temperature changes. If this expansion and contraction do not occur uniformly, it generates different stress levels and deformation. If the board’s temperature reaches the upper limit of Tg, it will begin to soften, resulting in permanent deformation.

2. The connection points (vias) between the PCB layers restrict the board’s expansion and contraction. Modern circuit boards are primarily multi-layered, featuring rivet-like connection points (vias) such as through holes, blind holes, and buried holes. These connection points impose constraints on the board, affecting its ability to expand and contract, which can indirectly lead to bending and warping.

3. The weight of the circuit board itself can cause dents and deformation. In a reflow furnace, a chain typically drives the board forward, using its edges as fulcrums to support the entire structure. If there are heavy components on the board or if the board is excessively large, this can create a sagging effect in the center, leading to bending.

4. The depth of the V-Cut and the connecting strips can impact the deformation of the board. Essentially, the V-Cut compromises the board’s structural integrity by creating V-shaped grooves, making it more susceptible to deformation.

How can we prevent bending and warping during the reflow process?

1. Mitigate the impact of temperature on board stress. Since “temperature” is the primary source of stress, lowering the reflow oven temperature or slowing the heating and cooling rates can significantly reduce the likelihood of bending and warping. However, this might lead to other issues, such as solder short circuits.

2. Use high Tg materials. Tg, or the glass transition temperature, is the point at which a material transitions from a glassy to a rubbery state. Lower Tg values mean the board softens more quickly in the reflow oven, prolonging its time in the rubbery state and increasing the risk of deformation. Higher Tg materials can enhance the board’s resistance to stress and deformation, although they tend to be more expensive.

3. Increase the thickness of the circuit board. To meet demands for lighter and thinner electronic products, board thickness has been reduced to 1.0mm, 0.8mm, or even 0.6mm. Such thin boards are particularly prone to deformation after the reflow process. If lightness and thinness are not critical, using a thickness of 1.6mm can significantly lower the risk of bending and deformation.

4. Reduce PCB size and minimize the number of panels. Most reflow furnaces drive the circuit board using chains; larger boards are more likely to dent and deform due to their own weight. Positioning the longer side of the board along the chain can help alleviate deformation caused by weight. Reducing the number of panels follows the same principle; when passing through the furnace, try to orient the narrower edge in the direction of travel to minimize depression.

5. Use furnace trays or fixtures. If the above methods are challenging to implement, consider using a reflow carrier or template to reduce deformation. These carriers help stabilize the circuit board, allowing it to cool below its Tg before hardening again, thereby maintaining its integrity. If a single-layer pallet does not sufficiently reduce deformation, adding a cover to clamp the board between upper and lower pallets can greatly mitigate issues during the reflow process. However, these trays can be costly and require manual handling.

6. Utilize routers instead of V-Cuts for panel separation. As V-Cuts compromise the structural strength between circuit boards, it’s advisable to avoid V-Cuts entirely or minimize their depth.

1. In the PCB manufacturing process, many circuit boards are susceptible to bending and warping during the Reflow stage. In severe cases, this can lead to issues such as incomplete soldering and tombstoning. How can we address this?

2. The causes of board bending and warping can vary for each board, but they ultimately stem from stress on the board exceeding the material’s tolerance. When the board experiences uneven stress, or when different areas of the board have varying capacities to withstand stress, bending and warping can occur.

3. So, where does this stress originate? The primary source of stress during the Reflow process is temperature. Heat not only softens the circuit board but also leads to distortion. Additionally, the material properties associated with thermal expansion and contraction contribute significantly to the bending issue.

4. Why do some boards exhibit different levels of bending and warping?

Before delving into the issues of board bending and warping, I recommend you review this article that analyzes the root causes and prevention strategies for PCB explosions. Some content will be relevant.

1. The uneven copper surface area on the circuit board can exacerbate bending and warping. Typically, large copper foil areas are included for grounding, and sometimes for the Vcc layer as well. If these copper foils are not evenly distributed across the board, it leads to uneven heat absorption and dissipation. Consequently, the board will expand and contract with temperature changes. If this expansion and contraction do not occur uniformly, it generates different stress levels and deformation. If the board’s temperature reaches the upper limit of Tg, it will begin to soften, resulting in permanent deformation.

2. The connection points (vias) between the PCB layers restrict the board’s expansion and contraction. Modern circuit boards are primarily multi-layered, featuring rivet-like connection points (vias) such as through holes, blind holes, and buried holes. These connection points impose constraints on the board, affecting its ability to expand and contract, which can indirectly lead to bending and warping.

3. The weight of the circuit board itself can cause dents and deformation. In a reflow furnace, a chain typically drives the board forward, using its edges as fulcrums to support the entire structure. If there are heavy components on the board or if the board is excessively large, this can create a sagging effect in the center, leading to bending.

4. The depth of the V-Cut and the connecting strips can impact the deformation of the board. Essentially, the V-Cut compromises the board’s structural integrity by creating V-shaped grooves, making it more susceptible to deformation.

How can we prevent bending and warping during the reflow process?

1. Mitigate the impact of temperature on board stress. Since “temperature” is the primary source of stress, lowering the reflow oven temperature or slowing the heating and cooling rates can significantly reduce the likelihood of bending and warping. However, this might lead to other issues, such as solder short circuits.

2. Use high Tg materials. Tg, or the glass transition temperature, is the point at which a material transitions from a glassy to a rubbery state. Lower Tg values mean the board softens more quickly in the reflow oven, prolonging its time in the rubbery state and increasing the risk of deformation. Higher Tg materials can enhance the board’s resistance to stress and deformation, although they tend to be more expensive.

3. Increase the thickness of the circuit board. To meet demands for lighter and thinner electronic products, board thickness has been reduced to 1.0mm, 0.8mm, or even 0.6mm. Such thin boards are particularly prone to deformation after the reflow process. If lightness and thinness are not critical, using a thickness of 1.6mm can significantly lower the risk of bending and deformation.

4. Reduce PCB size and minimize the number of panels. Most reflow furnaces drive the circuit board using chains; larger boards are more likely to dent and deform due to their own weight. Positioning the longer side of the board along the chain can help alleviate deformation caused by weight. Reducing the number of panels follows the same principle; when passing through the furnace, try to orient the narrower edge in the direction of travel to minimize depression.

5. Use furnace trays or fixtures. If the above methods are challenging to implement, consider using a reflow carrier or template to reduce deformation. These carriers help stabilize the circuit board, allowing it to cool below its Tg before hardening again, thereby maintaining its integrity. If a single-layer pallet does not sufficiently reduce deformation, adding a cover to clamp the board between upper and lower pallets can greatly mitigate issues during the reflow process. However, these trays can be costly and require manual handling.

6. Utilize routers instead of V-Cuts for panel separation. As V-Cuts compromise the structural strength between circuit boards, it’s advisable to avoid V-Cuts entirely or minimize their depth.