The PCBA foundry is a production technology for printed circuit boards, focusing primarily on the layout design and manufacturing of PCBA. Based on the number of layers in the circuit board, PCBA foundry materials are categorized into single-sided, double-sided, four-layer, six-layer, and other multi-layer circuit boards. So, what are the applications of PCBA foundry materials? Why has PCBA OEM become so popular today?

1. The application fields of PCBA foundry materials

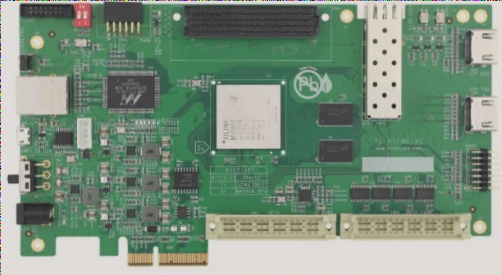

1. The future development trend of PCB OEM manufacturing technology is leaning towards higher density, greater precision, finer holes, thinner lines, smaller spacing, increased reliability, multi-layer configurations, high-speed transmission, and lightweight, thin profiles. The advantages of using PCBA foundry materials include reduced wiring and assembly errors,

1. Utilizing PCBA OEM materials significantly reduces equipment maintenance, debugging, and inspection time. The design can be standardized, enhancing interchangeability. High wiring density, compact volume, and lightweight properties facilitate the miniaturization of electronic equipment. This approach supports mechanized and automated production, boosting labor productivity and lowering the cost of electronic devices. Additionally, the bending resistance and precision of circuit boards made from PCBA OEM materials are particularly suited for high-precision instruments.

2. PCB OEM materials find extensive application in everyday life, especially in medical equipment. The rapid advancement of medical science is closely linked to the swift growth of the electronics industry. Many microbiological devices and similar equipment utilize single-board PCBA foundry materials, with production processes sometimes requiring currents as high as 100 amperes. Consequently, PCBA foundry materials are crucial in fields like arc welding, military applications, and cotton garment machinery.

3. PCB OEM materials are also prevalent in the lighting sector. Surrounding LED lights and high-intensity LEDs, small LEDs deliver high-brightness illumination and are often mounted on PCBA foundry alternatives built on aluminum substrates. This indicates that PCBA foundry materials possess essential application technologies. The use of LED lights demonstrates the extensive range of fields that PCBA foundry materials cover.

**PCBA Foundry Material**

2. **Reasons for the Popularity of PCBA Foundry Materials**

1. The growing popularity of PCBA OEM materials can largely be attributed to the rise of small-batch production businesses, which differ from traditional large-scale manufacturing. This service model offers greater reliability. Previously, batch requirements could lead to significant additional costs when production volumes were insufficient, sometimes reaching tens of thousands of yuan. As the market evolves, the barriers to entry have lowered, allowing more individuals to participate.

2. When opting for PCBA OEM materials, a certain minimum quantity is necessary for processing. Historically, product quantities often reached thousands, with few in the hundreds. This limitation affected early-stage hardware products, which struggled to find suitable production methods. Recently, the market landscape has adapted, offering more guarantees while simultaneously mitigating other challenges, effectively lowering the current barriers.

3. Many individuals choose PCBA OEM materials for the opportunity to enhance their production processes, which effectively shortens the overall production cycle. Early entrants in this sector often lacked certain functionalities, leading to various complications. By gaining a deeper understanding of the industry through accurate methodologies, one can uncover the inherent advantages driving the development of this field.

1. The application fields of PCBA foundry materials

1. The future development trend of PCB OEM manufacturing technology is leaning towards higher density, greater precision, finer holes, thinner lines, smaller spacing, increased reliability, multi-layer configurations, high-speed transmission, and lightweight, thin profiles. The advantages of using PCBA foundry materials include reduced wiring and assembly errors,

1. Utilizing PCBA OEM materials significantly reduces equipment maintenance, debugging, and inspection time. The design can be standardized, enhancing interchangeability. High wiring density, compact volume, and lightweight properties facilitate the miniaturization of electronic equipment. This approach supports mechanized and automated production, boosting labor productivity and lowering the cost of electronic devices. Additionally, the bending resistance and precision of circuit boards made from PCBA OEM materials are particularly suited for high-precision instruments.

2. PCB OEM materials find extensive application in everyday life, especially in medical equipment. The rapid advancement of medical science is closely linked to the swift growth of the electronics industry. Many microbiological devices and similar equipment utilize single-board PCBA foundry materials, with production processes sometimes requiring currents as high as 100 amperes. Consequently, PCBA foundry materials are crucial in fields like arc welding, military applications, and cotton garment machinery.

3. PCB OEM materials are also prevalent in the lighting sector. Surrounding LED lights and high-intensity LEDs, small LEDs deliver high-brightness illumination and are often mounted on PCBA foundry alternatives built on aluminum substrates. This indicates that PCBA foundry materials possess essential application technologies. The use of LED lights demonstrates the extensive range of fields that PCBA foundry materials cover.

**PCBA Foundry Material**

2. **Reasons for the Popularity of PCBA Foundry Materials**

1. The growing popularity of PCBA OEM materials can largely be attributed to the rise of small-batch production businesses, which differ from traditional large-scale manufacturing. This service model offers greater reliability. Previously, batch requirements could lead to significant additional costs when production volumes were insufficient, sometimes reaching tens of thousands of yuan. As the market evolves, the barriers to entry have lowered, allowing more individuals to participate.

2. When opting for PCBA OEM materials, a certain minimum quantity is necessary for processing. Historically, product quantities often reached thousands, with few in the hundreds. This limitation affected early-stage hardware products, which struggled to find suitable production methods. Recently, the market landscape has adapted, offering more guarantees while simultaneously mitigating other challenges, effectively lowering the current barriers.

3. Many individuals choose PCBA OEM materials for the opportunity to enhance their production processes, which effectively shortens the overall production cycle. Early entrants in this sector often lacked certain functionalities, leading to various complications. By gaining a deeper understanding of the industry through accurate methodologies, one can uncover the inherent advantages driving the development of this field.