The Evolution of Lead-Free PCBs: Navigating the Reliability Landscape

Lead-free PCB electronic products are becoming increasingly common in today’s market, sparking concerns about their reliability. The debate over whether lead-free options are more reliable than traditional tin-lead solder has divided experts. Understanding the nuances of this issue is crucial for making informed decisions.

Key Considerations for Lead-Free PCB Reliability:

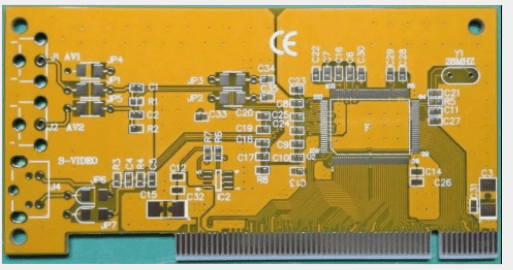

- Solder Alloy: The choice of solder alloy, such as Sn-Ag-Cu (SAC) or Sn-Cu, significantly impacts reliability in different soldering processes.

- Process Conditions: Soldering temperatures and board size play a role in determining the reliability of PCB components.

- Laminate Material: The properties of the laminate material can affect issues like delamination and copper cracks during lead-free soldering.

- Component Sensitivity: Certain components, like plastic-packaged devices, may be more sensitive to increased soldering temperatures.

- Mechanical Load: Mechanical stress from impacts or bending can lead to solder interconnection failures.

- Thermomechanical Load: Thermal cycling can cause solder joint failures due to damage accumulation and crack propagation.

- Acceleration Factor: Different solder alloys have unique acceleration coefficients that impact reliability.

It’s clear that the reliability of lead-free PCB solder interconnections is a complex interplay of various factors. By understanding these considerations, manufacturers and designers can navigate the evolving landscape of lead-free PCB technology with confidence.