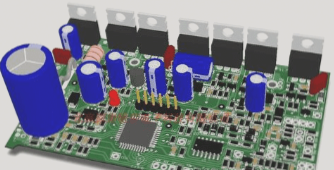

PCBA foundry materials are not commonly encountered in everyday life. However, these materials and their associated processes offer numerous advantages, although certain aspects require careful attention. Many individuals may find this topic unclear. This article aims to explore the factors influencing the price of the processing flow for OEM materials in PCBA. I hope this information proves beneficial to everyone.

1. Detailed processing flow of PCBA foundry materials:

1. PCBA processing project evaluation

When customers design products, a crucial evaluation is performed: design for manufacturability. This assessment is essential for ensuring quality control throughout the manufacturing process.

2. Confirm the cooperation and sign the contract.

After the negotiation, both parties agreed to collaborate and proceed with signing the contract.

3. Customers Provide Processing Information

Once the customer finalizes the product design, they submit the Gerber file, BOM list, and other engineering documents to the supplier. Typically, the supplier assigns a dedicated technician to review, confirm, and evaluate the specifics of the stencil printing, surface mount technology (SMT), and through-hole assembly processes.

4. Material Procurement, Inspection, and Processing

The customer prepays a portion of the project cost for the foundry materials (ranging from 30% to 80%, generally around 70% based on product profitability). Upon receipt of this payment, the supplier proceeds with component procurement. Once preparation is complete, production scheduling follows the PMC Plan.

5. SMT and DIP Processing

Materials undergo online production, with quality inspections conducted after the processes of screen printing, reflow soldering, AOI inspection, DIP assembly, and wave soldering.

6. Quality Inspection by the Quality Department

The quality department performs random inspections of the products and conducts repairs on any identified defects.

7. Packing, Shipping, and After-Sales Service

All products are packaged and shipped following production completion, using anti-static packaging bags. Additionally, after-sales service is monitored and tracked.

**PCBA Foundry Materials**

2. Factors Affecting the Price of PCBA Foundry Materials

1. The Versatility of PCBA Processing Materials

Material versatility encompasses two aspects:

Firstly, the material adheres to common industry standards.

Secondly, if no universal standard exists within the material industry, customization is required. In such cases, enhancing material versatility is essential.

2. The Complexity of the PCBA Product Portfolio

Product portfolio complexity refers to both the variety of products offered by the company and the availability of different specifications, models, colors, and other options for the same product.

3. The Scale of PCBA Processing

Large PCB assembly plants and distribution centers must align their operations with large product shipments to achieve economies of scale and profitability. Conversely, small electronics manufacturing facilities and distribution centers should align their shipments with their operational scale. Attempting to manage large wholesale goods may lead to overtime and operational inefficiencies.

—

Let me know if you need further adjustments!

1. Detailed processing flow of PCBA foundry materials:

1. PCBA processing project evaluation

When customers design products, a crucial evaluation is performed: design for manufacturability. This assessment is essential for ensuring quality control throughout the manufacturing process.

2. Confirm the cooperation and sign the contract.

After the negotiation, both parties agreed to collaborate and proceed with signing the contract.

3. Customers Provide Processing Information

Once the customer finalizes the product design, they submit the Gerber file, BOM list, and other engineering documents to the supplier. Typically, the supplier assigns a dedicated technician to review, confirm, and evaluate the specifics of the stencil printing, surface mount technology (SMT), and through-hole assembly processes.

4. Material Procurement, Inspection, and Processing

The customer prepays a portion of the project cost for the foundry materials (ranging from 30% to 80%, generally around 70% based on product profitability). Upon receipt of this payment, the supplier proceeds with component procurement. Once preparation is complete, production scheduling follows the PMC Plan.

5. SMT and DIP Processing

Materials undergo online production, with quality inspections conducted after the processes of screen printing, reflow soldering, AOI inspection, DIP assembly, and wave soldering.

6. Quality Inspection by the Quality Department

The quality department performs random inspections of the products and conducts repairs on any identified defects.

7. Packing, Shipping, and After-Sales Service

All products are packaged and shipped following production completion, using anti-static packaging bags. Additionally, after-sales service is monitored and tracked.

**PCBA Foundry Materials**

2. Factors Affecting the Price of PCBA Foundry Materials

1. The Versatility of PCBA Processing Materials

Material versatility encompasses two aspects:

Firstly, the material adheres to common industry standards.

Secondly, if no universal standard exists within the material industry, customization is required. In such cases, enhancing material versatility is essential.

2. The Complexity of the PCBA Product Portfolio

Product portfolio complexity refers to both the variety of products offered by the company and the availability of different specifications, models, colors, and other options for the same product.

3. The Scale of PCBA Processing

Large PCB assembly plants and distribution centers must align their operations with large product shipments to achieve economies of scale and profitability. Conversely, small electronics manufacturing facilities and distribution centers should align their shipments with their operational scale. Attempting to manage large wholesale goods may lead to overtime and operational inefficiencies.

—

Let me know if you need further adjustments!