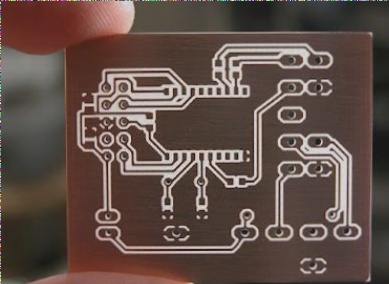

The copper wire on the impedance circuit board is detaching, and the manufacturer often attributes it to issues with the laminate. To help mitigate this problem, I’ve compiled some potential causes for your consideration:

1. **Over-etched Copper Foil:** Market-available electrolytic copper foils typically come in two types: single-sided galvanized (known as ashing foil) and single-sided copper-plated (known as red foil). The commonly discarded copper is usually galvanized copper above 70um. Foil below 18um, such as red and ash foils, typically lacks consistent copper adherence.

2. **Residual Etching Solution:** Occasionally, the etching parameters of the impedance circuit board may appear fine, but post-etching, residual etching solution can surround the copper wire on the PCB surface. Over time, this can lead to excessive undercutting and copper detachment, particularly evident on thin lines or during humid weather. Scrutinizing the stripped copper wire reveals a color change on the contact surface with the base layer (the “roughened surface”). The copper foil’s color differs from the norm, exposing the original copper color of the base layer, while the peeling strength of thicker lines remains normal.

3. **Unreasonable Circuit Design:** In cases where thick copper foil is used for overly thin circuit designs, excessive etching and copper detachment can result.

4. **Abnormal Electrolytic Copper Foil:** Electrolytic copper foils, as previously mentioned, undergo galvanization or copper-plating processes. Anomalies during these processes, such as irregular peaks or poor plating crystal branches, can lead to insufficient peeling strength of the copper foil. Consequently, PCBs made from such faulty foils may experience copper wire detachment upon impact during electronics assembly. Notably, inspecting the peeled-off copper wire reveals a roughened surface on the copper foil, indicating poor overall peeling strength.

5. **Poor Etching of Potion:** Even when etching parameters and operations appear normal, poor etching of the potion can result in an inadequately cleaned surface.

To avoid copper wire detachment issues, it’s advisable to select a manufacturer with robust process capabilities and quality materials. Choosing a manufacturer with low process capabilities or inferior sheet metal increases the risk of compromised finished product quality.

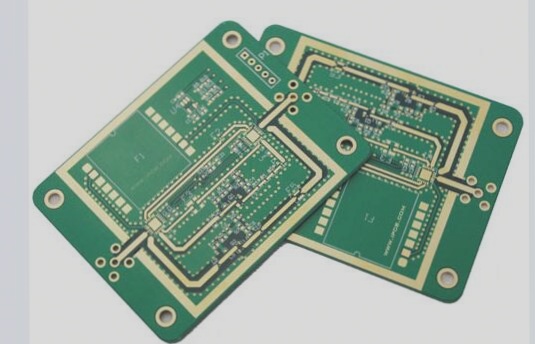

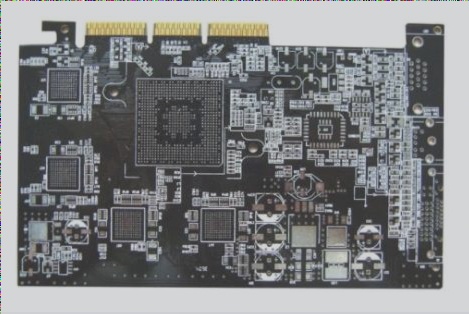

WellCircuits Limited specializes in producing high-precision double-sided PCB boards, multilayer PCBs, impedance PCB boards, blind buried via PCB boards, immersion gold PCB boards, and copper circuit boards.

1. **Over-etched Copper Foil:** Market-available electrolytic copper foils typically come in two types: single-sided galvanized (known as ashing foil) and single-sided copper-plated (known as red foil). The commonly discarded copper is usually galvanized copper above 70um. Foil below 18um, such as red and ash foils, typically lacks consistent copper adherence.

2. **Residual Etching Solution:** Occasionally, the etching parameters of the impedance circuit board may appear fine, but post-etching, residual etching solution can surround the copper wire on the PCB surface. Over time, this can lead to excessive undercutting and copper detachment, particularly evident on thin lines or during humid weather. Scrutinizing the stripped copper wire reveals a color change on the contact surface with the base layer (the “roughened surface”). The copper foil’s color differs from the norm, exposing the original copper color of the base layer, while the peeling strength of thicker lines remains normal.

3. **Unreasonable Circuit Design:** In cases where thick copper foil is used for overly thin circuit designs, excessive etching and copper detachment can result.

4. **Abnormal Electrolytic Copper Foil:** Electrolytic copper foils, as previously mentioned, undergo galvanization or copper-plating processes. Anomalies during these processes, such as irregular peaks or poor plating crystal branches, can lead to insufficient peeling strength of the copper foil. Consequently, PCBs made from such faulty foils may experience copper wire detachment upon impact during electronics assembly. Notably, inspecting the peeled-off copper wire reveals a roughened surface on the copper foil, indicating poor overall peeling strength.

5. **Poor Etching of Potion:** Even when etching parameters and operations appear normal, poor etching of the potion can result in an inadequately cleaned surface.

To avoid copper wire detachment issues, it’s advisable to select a manufacturer with robust process capabilities and quality materials. Choosing a manufacturer with low process capabilities or inferior sheet metal increases the risk of compromised finished product quality.

WellCircuits Limited specializes in producing high-precision double-sided PCB boards, multilayer PCBs, impedance PCB boards, blind buried via PCB boards, immersion gold PCB boards, and copper circuit boards.