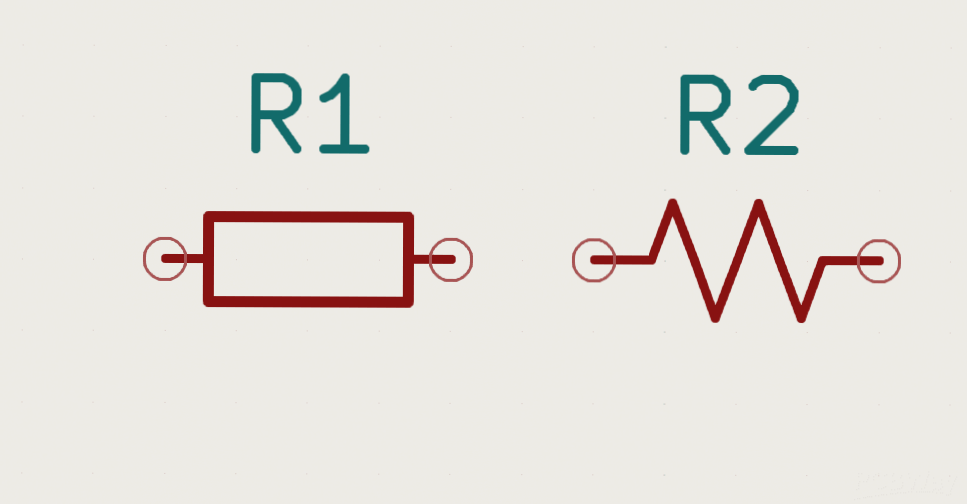

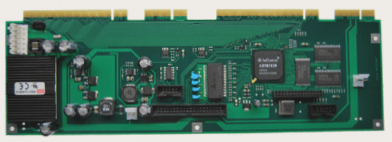

1. When proofing PCB plug-in component pads, it is crucial for the pad sizes to be appropriate. If a pad is excessively large, the solder’s spreading area will increase, resulting in incomplete solder joints. Conversely, if the pad is too small, the surface tension of the copper foil becomes insufficient, leading to non-wetting solder joints. Additionally, if the gap between the aperture and the component lead is too wide, soldering can become problematic. An ideal soldering condition occurs when the aperture is 0.05 to 0.2 mm wider than the lead and 2 to 2.5 times the diameter of the pad.

2. The PCB proofing process must adhere to pad requirements that stipulate a minimum diameter at least 0.5 mm larger than the largest diameter of the small hole flange of the welding terminal. Test pads must be included for all nodes in compliance with ANSI/IPC2221 standards. A node represents an electrical connection point between two or more components. Each test pad should include a signal name (node signal name), the x-y coordinates related to the reference point of the printed circuit board, and the specific coordinate position of the test pad, clearly indicating which side of the printed circuit board the test pad is situated on.

**Considerations for PCB Proofing Regarding Pad Aperture Size**

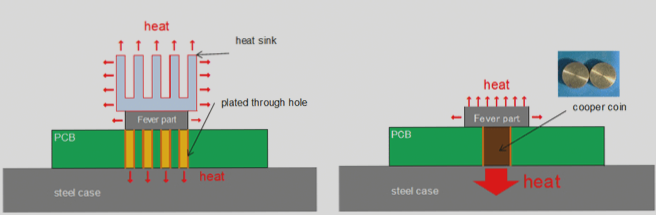

The aspect ratio of the plated through hole significantly affects the PCB proofing manufacturer’s ability to achieve effective plating within the hole, which is crucial for the reliability of the PTH/PTV structure. When the hole size is less than one-quarter of the basic circuit board’s thickness, the tolerance should be increased by 0.05mm. If the hole diameter is 0.35mm or smaller and the aspect ratio is 4:1 or greater, the PCB proofing manufacturer should employ suitable methods to cover or block the plated through holes to prevent solder ingress. Generally, the ratio of the circuit board’s thickness to the pitch of the plated through holes should be less than 5:1. Information regarding the fixed equipment for SMT is essential, along with the warming technology of the PCB assembly layout, to enhance circuit development with the aid of “fixed equipment for circuit testing,” commonly known as “fixed equipment for nail bed.” This ensures testability.

To achieve this intent, it is necessary to:

1. Avoid probing plated through-holes at both ends of the printed circuit board. Place the test top through hole on the non-component/soldering side of the PCB, allowing for the use of reliable and cost-effective equipment. Minimize the variety of hole sizes.

2. The diameter of the test pad designed for prospecting should be no less than 0.9mm.

3. Avoid relying on the edge of the connector pointer for pad testing, as the test probe can easily damage the gold-plated pointer.

4. The space surrounding the test pad should exceed 0.6mm but be less than 5mm. If a component’s height exceeds 6.7mm, position the test pad at least 5mm away from the component.

5. Ensure no components or test pads are placed within 3mm of the edge of the printed circuit board.

6. Position the test pad at the center of a 2.5mm hole in a grid format. Whenever possible, commit to using standard probes and a more reliable fixture.

These considerations for PCB proofing details are all aimed at ensuring product quality.