Take an example of any electronic device, and you will find a PCB in it. Every smartphone, laptops, cars, and other gadgets have PCBs. So, considering this advanced world is almost impossible without this semiconductor chip. While most people know there are these Printed Circuit Boards inside everyday electronics we use, they do not know much about their design and manufacturing process.

There are a lot of interesting facts to know about PCB design and manufacturing that everyone must know. So, here we will be exploring some of the most interesting ones.

Top 13 interesting facts you need to know about PCB design and manufacturing

While it may seem simple, there are many things related to PCBs’ design and manufacturing process. So, let us explore the most important facts you need to know about PCBs, their design, and manufacturing.

Designing your PCB always starts with the size of the PCB

A PCB turns an idea into a physical product with different functionalities. It is an electrical engineering process, and creating the PCBs means creating the electronics’ brains.

So, when designing the PCB for an electronic device, it is important to know its size. The size of the product or the enclosure where you will place the PCB decides how you will design the PCB. Technically you can design PCBs of large sizes, but technologies are focusing on making smaller PCBs to save space and other resources.

One cannot simply throw all the components on a chip and call it a PCB

Anyone with knowledge of circuits can design a schematic for their PCB. However, designing the schematic is not the only important thing. As you design the PCB for a product that humans will use, the way humans interact with it is one of the major concerns.

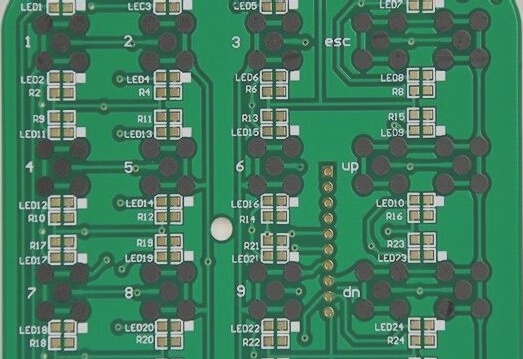

Different LEDs can give visual information, buttons taking input, and jacks for communicating with devices. So, when a PCB is being designed, it is necessary to keep user experience in mind because otherwise, the usability score of that PCB will be 0. Designing a PCB so that anyone can use it effortlessly matters a lot.

Prototyping saves time and cost during the PCB design and manufacturing process.

Whenever a PCB is manufactured on a large scale, we design it and then make a prototype. It is necessary because prototyping provides a physical copy of the PCB. That prototype goes through all the different technicality and functionality testing to ensure that it works as per the requirements.

More importantly, any issue at the prototyping stage can be resolved without huge losses. Consider manufacturing a lot of 2000 PCBs. After the whole production process is complete, the whole lot gets rejected because of a minor fault. Prototyping is important as it saves time, resources, and cost.

You need to choose PCB according to layers for different projects

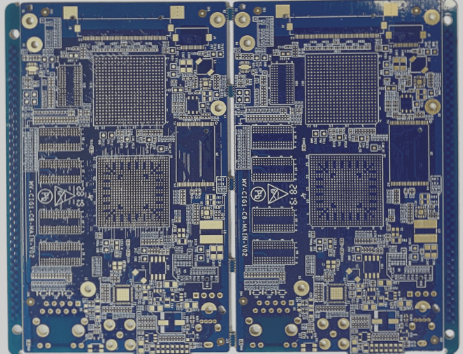

If you have seen different PCBs, you might wonder why some are extremely thin while some are more durable and long-lasting. PCBs are made in different layers. The number of layers of a PCB speaks about its complexity and manufacturing features. Generally, there are 3 main options and below are their applications:

- PCBs with 2 layers are made for simple products that mainly include toys

- PCBs with 4 layers are made for a little more complex functionalities, and they power the brains of IoT products

- PCBs with 6 to 8 layers are the most complex, and they go inside the feature and performance-hungry devices like smartphones and tech gadgets.

This simple printed circuit chit has many specifications you need to consider.

If you think that you will only need to consider the size and layer count of the PCB, then you are wrong. When you are going to manufacture a PCC, there are a lot of specifications that you need to consider. Most of these specifications have a technical role in the functionality and performance of the PCB. The most important specifications of your PCB that you need to consider apart from the size and layers are:

- Material of the PCB. Several materials are available like phenolic cotton paper, epoxy and cotton paper, glass and epoxy, etc.

- The thickness of the PCB

- Color of the PCB

- The surface finish of the PCB. Many options are available, including ENIG, DIG, OSP, etc.

- Copper weight of the PCB

- Gerber file of the PCB design

A PCB always starts from a document

In the older days, when the PCB designing process was not that complex, engineers used to design the schematic on paper or board. However, today things have gotten very different, and most computer and laptop-based tools help efficiently design the schematic of your PCB. Either way, the process starts with a document.

This document is uploaded to the PCB fabrication machines, which manufacture the PCB.

A PCB never needs wires on it if it is well designed.

For the transmission of data or power, no wires are required in a PCB. It consists of copper traces instead of wires which takes less space and is more effective. Traces are small, which allows for to manufacture of a tinner board. However, remember that copper is expensive. Therefore, you must consider this factor in your budget while planning PCB production.

In some cases, there are wires required on a PCB. Those are the cases usually where the copper trace cannot hold the amount of current passing through it. So, thicker wires are soldered on the required parts of the PCB. Those wires can be hard copper insulated wires or soft copper insulated wires. However, using uninsulated wires is not the right choice at all.

The components are not on the PCB right from the beginning

Do you also think the PCB comes out from the manufacturing machine as it is in your electronics? You are wrong if you think so because PCB manufacturing is a process divided into several parts. In most cases, the PCB is manufactured first, and then it goes for the application of soldering paste.

After that, the computer visually tests the solder paste application. The next step includes applying components to the PCB. After this process is complete, PCB takes the shape in which it is present inside your electronics.

When mounting components on a PCB, there are several options to go for

PCB component mounting is a process where components are attached to the printed circuits. Soldering is the most common option, while some components also have a snap-on connector. However, when we consider the soldering option for mounting components onto a PCB, several options are also available. Some of those include:

- Reflow soldering

- Iron soldering

- Wave soldering

The soldering method is selected according to its efficiency, considering the requirements and specifications of the PCB.

Testing is an essential part of PCB design and manufacturing.

PCBs are not shipped or deployed right after making them. An important process to be done after manufacturing is complete is testing and quality assurance. It is necessary to ensure that the PCB works as required because otherwise, it will be useless. Misplaced components and solder bridges can cause several issues with a PCB. So, different types of tests are conducted on a PCB, including:

- In-Circuit Testing

- Automatic Optical Inspection

- X-Ray

It can be shipped or deployed only after the PCB passes all the testing and QA checks.

You can customize PCBs today.

Suppose you are planning to have unique specifications in your PCB. It is possible, and you can have as many features as you need. However, the process will be time-consuming and costly. To make the customization manageable, experts have certain pre-specified parameters that allow them to work quickly.

It does not mean these parameters bind you because you can still have as many new characteristics as you want.

PCB technology is always evolving.

PCB design technology is rapidly evolving, just like any other advancement that experts have to keep up with. You do not want to use the old technique of designing PCB that no one else is using. You can take the example of the introduction of biodegradable materials in PCB. Professionals are looking for ways to make their PCB eco-friendly, and using such materials seems like a great option.

One of the most parts of PCB designing and manufacturing is the budget.

If you plan to create your board, remember that 31% of the cost will go to designing and manufacturing PCB. You must consider this factor while collecting components for your board to ensure you can easily manage your budget. You can try new features and get better results if you have the required investment.

Conclusion

Today designing and manufacturing a PCB is not a difficult task as many options are readily available. Tools let you make your schematic, and then you can upload that schematic to any online PCB manufacturer of your choice. Within a few days, your PCB will be delivered to your doorstep.

By keeping all these facts about PCBs, their design, and manufacturing, your experience with these chips will be even better. So, whether you are planning on a DIY project or working on a product, always keep these facts about PCBs in mind to help yourself through the process.