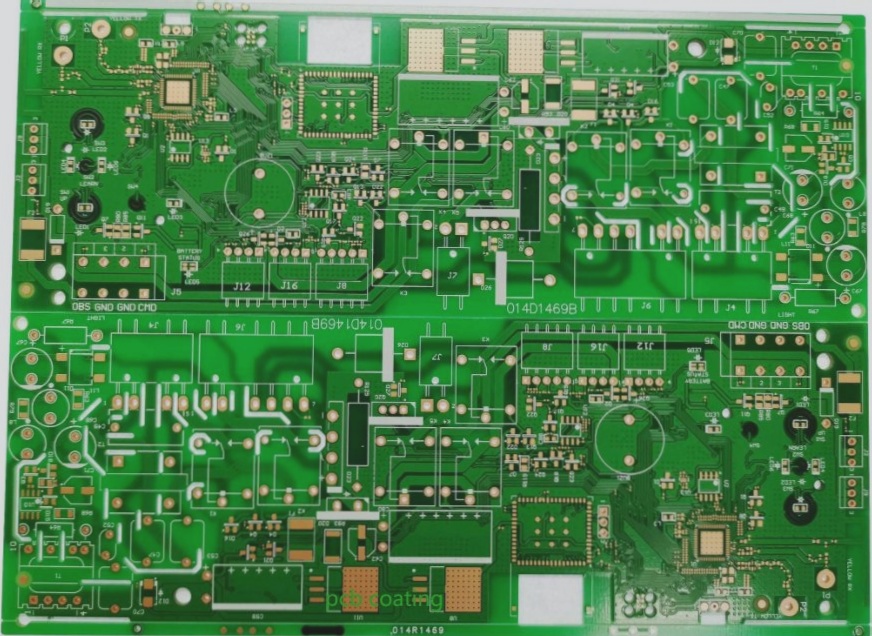

1. “ate load board” was a term used in the semiconductor industry several years ago for automatic test equipment (ATE) PCBs. However, in recent years, they have been referred to as “device interface boards (DIBs)” or “processor interface boards (HIBs)” in the semiconductor industry.

2. Chip manufacturers require rapid turnaround and high-quality evaluation of their newly produced and highly advanced products when ordering test boards, regardless of brand. This exceeds the requirements of previous generations of test boards.

3. This is because chips are being manufactured much faster than they were a few years ago. Chip manufacturers are keen to test their products as soon as possible because they are producing them at a faster rate.

4. The manufacturing time frame used to be two to three months, but today they are close to six to eight weeks. Chip manufacturers are demanding that their new chips be tested using ATE load board as soon as possible, and they do not want millions of dollars worth of chips to sit idle.

ATE PCB suppliers now have a shortened delivery timeline of six to eight weeks to produce the required test boards for chip manufacturers, as opposed to the previous two to three months. Suppliers may also offer additional services, such as wafer testing and inspection, processing, cutting, and semiconductor packaging, in their quotations in order to provide added value to chip manufacturers. Designing high-quality ATE PCBs requires expertise in design knowledge and intelligent design methods, as well as an understanding of the subtle differences associated with reducing ball grid array (BGA) packaging and reducing the spacing between BGA balls.

Quality and accuracy are essential in the design of ATE PCBs. The design process must adhere to strict manufacturing standards to ensure accurate test board results. This includes considerations such as the placement of bypass capacitors and voltage limitations, especially as designers are now building 30 to 50 ply boards. As BGA packaging technology continues to advance, with pin spacing now as small as 0.25 to 0.3 millimeters, experienced ATE PCB designers must carefully consider the design constraints and wiring width in order to ensure accuracy.

Technological advances in BGA spacing and wiring widths require experienced ATE PCB designers to adapt their layout and wiring techniques. For example, when working with a 0.3mm spacing BGA, designers must use narrower routing of 3 to 4 mils to accommodate the smaller scale. Differential pair widths and high-speed routing must also be carefully considered to meet the requirements of the chip manufacturer. The manufacturing workshop must ensure that the differential pairs are correctly impedance matched with a tolerance of 5%, as any discrepancies will affect the accuracy of the chip test results.

2. Chip manufacturers require rapid turnaround and high-quality evaluation of their newly produced and highly advanced products when ordering test boards, regardless of brand. This exceeds the requirements of previous generations of test boards.

3. This is because chips are being manufactured much faster than they were a few years ago. Chip manufacturers are keen to test their products as soon as possible because they are producing them at a faster rate.

4. The manufacturing time frame used to be two to three months, but today they are close to six to eight weeks. Chip manufacturers are demanding that their new chips be tested using ATE load board as soon as possible, and they do not want millions of dollars worth of chips to sit idle.

ATE PCB suppliers now have a shortened delivery timeline of six to eight weeks to produce the required test boards for chip manufacturers, as opposed to the previous two to three months. Suppliers may also offer additional services, such as wafer testing and inspection, processing, cutting, and semiconductor packaging, in their quotations in order to provide added value to chip manufacturers. Designing high-quality ATE PCBs requires expertise in design knowledge and intelligent design methods, as well as an understanding of the subtle differences associated with reducing ball grid array (BGA) packaging and reducing the spacing between BGA balls.

Quality and accuracy are essential in the design of ATE PCBs. The design process must adhere to strict manufacturing standards to ensure accurate test board results. This includes considerations such as the placement of bypass capacitors and voltage limitations, especially as designers are now building 30 to 50 ply boards. As BGA packaging technology continues to advance, with pin spacing now as small as 0.25 to 0.3 millimeters, experienced ATE PCB designers must carefully consider the design constraints and wiring width in order to ensure accuracy.

Technological advances in BGA spacing and wiring widths require experienced ATE PCB designers to adapt their layout and wiring techniques. For example, when working with a 0.3mm spacing BGA, designers must use narrower routing of 3 to 4 mils to accommodate the smaller scale. Differential pair widths and high-speed routing must also be carefully considered to meet the requirements of the chip manufacturer. The manufacturing workshop must ensure that the differential pairs are correctly impedance matched with a tolerance of 5%, as any discrepancies will affect the accuracy of the chip test results.