Features of PCB Surface Mount Technology

1. High Assembly Density, Small Size, and Lightweight Design

The adoption of surface mount technology (SMT) results in components that are approximately 1/10th the size and weight of traditional through-hole components. This reduction in volume and weight can lead to a 40% to 60% decrease in the overall size of electronic products and a 60% to 80% reduction in weight.

2. High Reliability and Enhanced Vibration Resistance

SMT offers improved product reliability due to significantly lower defect rates in solder joints. Additionally, it provides better high-frequency performance, reducing electromagnetic and radio frequency interference.

3. Ease of Automation and Improved Production Efficiency

Surface mount technology enables automated assembly, leading to increased production efficiency. This automation can result in cost reductions of 30% to 50%, along with savings in materials, energy, equipment, labor, and time.

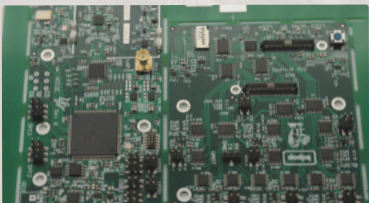

Why Use Surface Mount Technology (SMT)

PCB products are transitioning towards miniaturization, necessitating the use of surface mount components over traditional through-hole components. Advanced functionality in PCBs, especially with large-scale and highly integrated ICs, demands the efficiency of surface mount technology to meet market demands and enhance competitiveness.

PCB products are transitioning towards miniaturization, necessitating the use of surface mount components over traditional through-hole components. Advanced functionality in PCBs, especially with large-scale and highly integrated ICs, demands the efficiency of surface mount technology to meet market demands and enhance competitiveness.

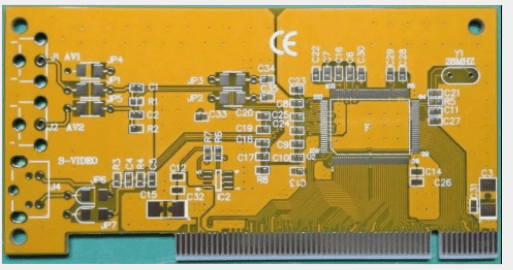

Surface Mount Chip

Selective Soldering and Wave Soldering Equipment Procurement

1. Size

Consider the size of the PCBs you need to handle, including the number of panels for productivity and cost-effectiveness. The machine’s accommodation size will also depend on factors like scrap or frame surrounding the PCB and pallet securing requirements.

2. Floor Area

Assess the available floor space for the selective soldering machine, considering its length and the handling/storage of circuit boards around it. Proper planning for PCB loading and unloading is crucial for efficient operation.

3. Machine Maintenance

Choose a selective soldering machine with low maintenance costs if running continuously during production shifts. Some systems may require more frequent maintenance for optimal performance.

4. Solder Pots

Determine the number of solder pots needed, considering options for leaded and lead-free solder to minimize changeover time. Multiple solder pots can enhance throughput efficiency.

5. Solder Nozzles

Select solder nozzle sizes and types based on component access needs. Limiting variety can boost throughput and reduce costs, with smaller or longer nozzles for better access and larger nozzles for faster soldering.

6. Nitrogen Supply

Ensure high-purity nitrogen supply for selective soldering, with options for on-site nitrogen generation or external storage tanks based on usage and site constraints.

7. Throughput

Consider flux application and soldering times for optimal process performance and efficiency.

8. Warm-Up

Provide top and bottom heating for PCBs before and after soldering, adjusting heat levels for multiple soldering or reflow stages as needed.

9. PCB and Assembly Handling

PCB Handling and Optional Features

The handling of PCBs can be done manually or through automated systems. For increased efficiency during longer production runs, consider adding a PCB stacker at the input/output stages. Alternatively, if the PCB requires loading components in parallel with soldering, a conveyor system may be a more suitable choice.

Optional Features

When selecting a PCB system, consider the optional features available. These can range from standard features to add-ons. For instance, features like detecting and compensating for PCB bending or warping may be essential based on your specific requirements.

Machine Configuration

Anticipate future changes in your production needs, such as adding more solder joints, flux, or preheating. In such cases, a modular system that allows for easy configuration changes may be more beneficial than a fixed system.

Shenzhen Longgang SMT Chip Processing

Selecting the right capital equipment for your business involves considering various factors. While some decisions may be straightforward, others may require experimentation to determine the most suitable system for your unique needs.

The Importance of Using No-Clean Processes in PCB Manufacturing

The adoption of no-clean processes in surface mount technology is crucial in reducing environmental impact and improving product quality. These processes help minimize water pollution, air pollution, and corrosion on PCBs, leading to cost savings and enhanced electrical performance.

- No-clean processes prevent water and soil pollution caused by PCB cleaning.

- Using organic solvents for cleaning can harm the atmosphere and contribute to air pollution.

- Residues left by cleaning agents can lead to corrosion, affecting product quality.

- No-clean processes reduce cleaning costs and maintenance expenses.

- Flux residue control ensures visual appearance requirements are met.

- No-clean processes have passed international safety tests for stability and non-corrosiveness.

If you have any PCB manufacturing needs, feel free to contact us.