To begin, it’s crucial to recognize that both FFC and FPC share a core objective: enabling signal transmission between electronic devices. As a vital link in this process, cable connections are essential for ensuring signal stability and integrity. So, how do FFC and FPC differ?

FFC, or Flexible Flat Cable, is a flat, flexible cable primarily used for internal connector connections. It consists of multiple layers of polyester film insulation, bonded together through high-temperature heat pressing, resulting in a compact, flat connection structure. Thanks to its lightweight and flexible nature, FFC finds widespread use in various mobile devices, including cell phones and tablet PCs.

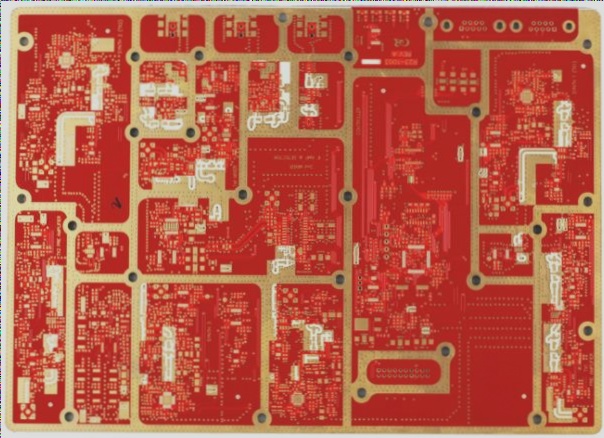

Conversely, FPC, or Flexible Printed Circuit, is a bendable printed circuit board. It utilizes polyimide or polyester film as its substrate, with a metal conductive layer affixed to the surface, allowing it to be bent, twisted, and even folded freely. Due to its high plasticity and stability, FPC is commonly employed in applications that necessitate frequent bending, such as automotive internal wiring and electronic cigarettes.

1. In specific applications, what are the advantages and disadvantages of FFC and FPC?

2. Firstly, from a cost perspective, FFC is generally more affordable. Its simple structure and mature production process contribute to a lower price point. Conversely, FPC utilizes more advanced technologies, resulting in higher costs.

3. Secondly, when it comes to performance, FPC excels. With a metal conductive layer, FPC offers superior conductivity and signal transmission quality compared to FFC. Additionally, FPC can support multi-layer stacking, enhancing circuit complexity and integration.

4. However, despite FPC’s performance benefits, FFC has unique applications. Its flexibility and lightweight characteristics make it the preferred choice in scenarios requiring significant bending and movement.

5. In conclusion, both FFC and FPC have their strengths, and the decision on which to use depends on specific application scenarios and requirements. Looking ahead, with advancements in technology and market dynamics, we anticipate ongoing innovation and enhancement of these two cable connection methods to better support human digital life.