Electronic equipment demands high performance, high speed, lightweight, thinness, and miniaturization. As a multidisciplinary industry, PCB is the most critical technology for high-end electronic equipment, whether in terms of rigidity, flexibility, rigid-flex combined multilayer boards in PCB products, or module substrates used for IC packaging substrates, they have made significant contributions to high-end electronic equipment. The PCB industry holds a crucial position in electronic interconnection technology.

Looking back at the challenging journey of China’s PCB industry over the past 50 years, today it has etched a glorious chapter in the history of global PCB development. In 2006, China’s PCB output value reached nearly 13 billion U.S. dollars, establishing itself as the world’s largest PCB producer.

Regarding the current development trends in PCB technology, I offer the following insights:

1. Advancement in High-Density Interconnection Technology (HDI)

HDI represents the most advanced technology in contemporary PCBs, bringing fine wires and small apertures to PCB design. The application of HDI multi-layer boards in terminal electronic products, such as mobile phones, showcases cutting-edge technology. In mobile phones, micro-wires on PCB motherboards (50μm-75μm/50μm-75μm, wire width/spacing) have become the norm, along with thinner conductive layers and boards. The refined conductive patterns enable high-density and high-performance electronic equipment. Over the past two decades, HDI has driven the development of mobile phones, boosting information processing, control of basic frequency functions in LSI and CSP chips (packages), as well as packaging template substrates. It is imperative to continue developing along the path of HDI.

2. Promising Prospects for Optoelectronic PCB

Utilizing optical path layers and circuit layers to transmit signals, this innovative technology focuses on manufacturing the optical path layer (optical waveguide layer) using methods like lithography, laser ablation, and reactive ion etching. This technology has already been industrialized in Japan and the United States.

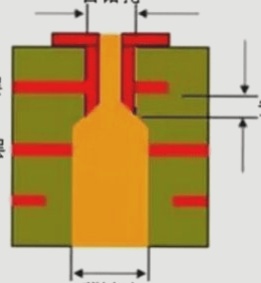

3. Component Embedding Technology Shows Robust Potential

This technology involves placing semiconductor devices (active components) or electronic components (passive components) within the inner layers of the PCB. Mass production of “component embedded PCBs” has begun, ushering in significant changes in functional integrated circuits of PCBs. To further develop this technology, challenges in analog design methods need to be addressed, along with ensuring production technology, quality inspection, and reliability assurance are prioritized. Resources should be allocated to systems encompassing design, equipment, testing, and simulation to sustain its vitality.

4. Updating Manufacturing Processes and Introducing Advanced Equipment

4.1. Manufacturing Process

While subtractive manufacturing methods remain prevalent, low-cost processes like additive and semi-additive methods are starting to emerge alongside the matured HDI manufacturing. Novel processes such as using nanotechnology for metallized holes and simultaneous formation of conductive patterns in flexible PCBs are being explored. Additionally, high-reliability and high-quality printing methods like inkjet PCB processes are gaining importance.

4.2. Advanced Equipment

Advanced equipment including production machinery for fine wires, new high-resolution photomasks and exposure devices, laser direct exposure devices, uniform plating equipment, as well as manufacturing and installation equipment for embedded components (passive and active components) are essential for the evolution of PCB technology.

5. Enhancing Materials Development in PCBs

Rigid and flexible PCB materials must adapt to the global shift towards lead-free electronic products by enhancing heat resistance. New materials with high Tg, small thermal expansion coefficients, low dielectric constants, and excellent dielectric loss tangents are continuously being developed.

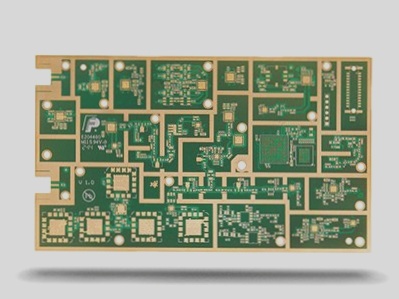

WellCircuits Limited, a specialized manufacturer, produces high-precision double-sided, multi-layer, impedance, blind buried vias, and thick copper circuit boards. Their product range includes HDI boards, thick copper boards, backplanes, rigid-flex combinations, buried capacitance and resistance boards, and Golden Finger boards, catering to diverse customer requirements.

Looking back at the challenging journey of China’s PCB industry over the past 50 years, today it has etched a glorious chapter in the history of global PCB development. In 2006, China’s PCB output value reached nearly 13 billion U.S. dollars, establishing itself as the world’s largest PCB producer.

Regarding the current development trends in PCB technology, I offer the following insights:

1. Advancement in High-Density Interconnection Technology (HDI)

HDI represents the most advanced technology in contemporary PCBs, bringing fine wires and small apertures to PCB design. The application of HDI multi-layer boards in terminal electronic products, such as mobile phones, showcases cutting-edge technology. In mobile phones, micro-wires on PCB motherboards (50μm-75μm/50μm-75μm, wire width/spacing) have become the norm, along with thinner conductive layers and boards. The refined conductive patterns enable high-density and high-performance electronic equipment. Over the past two decades, HDI has driven the development of mobile phones, boosting information processing, control of basic frequency functions in LSI and CSP chips (packages), as well as packaging template substrates. It is imperative to continue developing along the path of HDI.

2. Promising Prospects for Optoelectronic PCB

Utilizing optical path layers and circuit layers to transmit signals, this innovative technology focuses on manufacturing the optical path layer (optical waveguide layer) using methods like lithography, laser ablation, and reactive ion etching. This technology has already been industrialized in Japan and the United States.

3. Component Embedding Technology Shows Robust Potential

This technology involves placing semiconductor devices (active components) or electronic components (passive components) within the inner layers of the PCB. Mass production of “component embedded PCBs” has begun, ushering in significant changes in functional integrated circuits of PCBs. To further develop this technology, challenges in analog design methods need to be addressed, along with ensuring production technology, quality inspection, and reliability assurance are prioritized. Resources should be allocated to systems encompassing design, equipment, testing, and simulation to sustain its vitality.

4. Updating Manufacturing Processes and Introducing Advanced Equipment

4.1. Manufacturing Process

While subtractive manufacturing methods remain prevalent, low-cost processes like additive and semi-additive methods are starting to emerge alongside the matured HDI manufacturing. Novel processes such as using nanotechnology for metallized holes and simultaneous formation of conductive patterns in flexible PCBs are being explored. Additionally, high-reliability and high-quality printing methods like inkjet PCB processes are gaining importance.

4.2. Advanced Equipment

Advanced equipment including production machinery for fine wires, new high-resolution photomasks and exposure devices, laser direct exposure devices, uniform plating equipment, as well as manufacturing and installation equipment for embedded components (passive and active components) are essential for the evolution of PCB technology.

5. Enhancing Materials Development in PCBs

Rigid and flexible PCB materials must adapt to the global shift towards lead-free electronic products by enhancing heat resistance. New materials with high Tg, small thermal expansion coefficients, low dielectric constants, and excellent dielectric loss tangents are continuously being developed.

WellCircuits Limited, a specialized manufacturer, produces high-precision double-sided, multi-layer, impedance, blind buried vias, and thick copper circuit boards. Their product range includes HDI boards, thick copper boards, backplanes, rigid-flex combinations, buried capacitance and resistance boards, and Golden Finger boards, catering to diverse customer requirements.