2. Apple stands out as a staunch advocate of flexible circuit boards, incorporating as many as 16 FPCs in its iPhones, thereby making it the world’s largest purchaser of flexible PCBs. The top 6 FPC manufacturers globally primarily cater to such demand. Samsung, Huawei, OPPO, and other manufacturers have followed suit by significantly increasing FPC usage in their smartphones, influenced by Apple’s example.

3. Smartphones, as the primary growth driver for flexible circuit boards, have benefited immensely from Apple’s influential demonstration effect. Consequently, the penetration of flexible PCBs has seen rapid expansion, maintaining robust growth annually since 2009. It has emerged as the sole bright spot in the PCB industry since 2017, being the only segment to achieve positive growth.

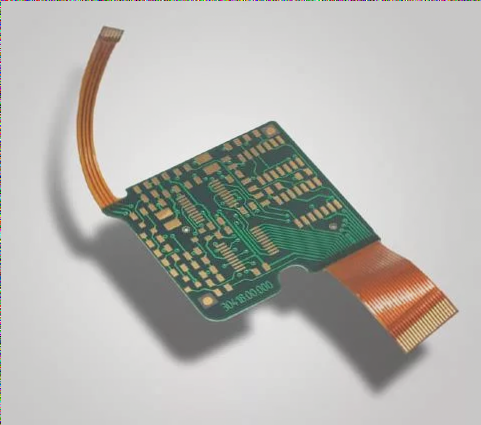

Flexible PCB

The flexible circuit board manufacturing industry emerged in the 1960s, with the United States and other technologically advanced countries initially applying FPC in aerospace, military, and other high-tech electronic products. Following the Cold War, FPC began transitioning to civilian products. By the early 21st century, the rapid growth of the consumer electronics sector propelled the flexible PCB industry into a period of vigorous expansion.

However, due to escalating production costs in Europe and the United States, the focus of FPC production gradually shifted to Asia, marking the initial wave of industry relocation. This shift stimulated rapid growth in FPC industries in countries like Japan, South Korea, and Taiwan, renowned for their robust manufacturing foundations and experience.

In recent years, production costs in Japan, South Korea, and Taiwan have continued to rise, prompting a new round of industrial migration in the FPC sector. Manufacturers from developed countries have increasingly invested in and established factories in China. As the primary host of the flexible PCB industry, China has reaped substantial benefits from this new wave of industrial transfer. Currently, China leads the world in total output value of flexible circuit boards.

Polyimide Stiffener of Flexible PCB

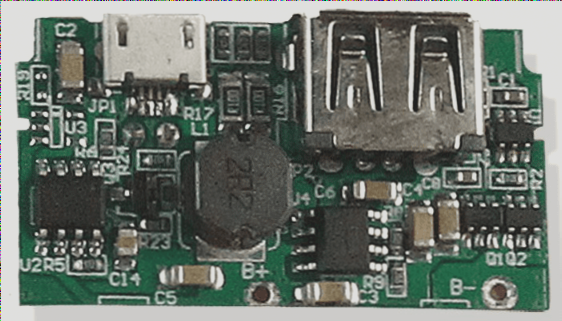

1. At present, the production process of flexible circuit boards mainly includes cutting, punching, drilling, copper plating, dry film application, exposure, development, etching, film removal, cleaning, protective film coating, lamination, pure tin plating, gold plating, silk screen printing, final punching, electrical testing, reinforcing film lamination, functional testing, and other processes.

2. Flexible Printed Circuit, abbreviated as FPC, also known as flexible circuit board or flexible PCB, boasts high wiring density, lightweight, and thin profile.

3. With the expansive market for FPCs in China, major firms from Japan, the United States, and Taiwan have established manufacturing facilities there. By 2016, flexible circuit boards had made significant advancements akin to their rigid counterparts.

4. Nonetheless, adhering to the product life cycle theory of “introduction-growth-maturity-decline-termination,” FPCs currently reside in the transitional phase between maturity and decline. To maintain market dominance until a superior alternative emerges, innovation is imperative. Only through innovation can FPCs transcend this cycle.

Thickness: The thickness of flexible PCBs needs to be reduced while maintaining flexibility.

Folding Resistance: Flexibility is inherent to FPCs, and future flexible PCBs must withstand bending over 10,000 times. Achieving this requires superior substrates.

Cost: Currently, flexible PCBs are significantly more expensive than traditional PCBs. Lowering the cost of FPCs would expand the market substantially.

Manufacturing Standards: To meet diverse requirements, FPC manufacturing processes must be enhanced. This includes stricter criteria for minimum aperture, line width, and line spacing.