Performance Comparison of Common Film Substrates

- The film substrate serves as the carrier for conductors and the insulating medium between lines, allowing for bending and curling. Commonly used substrates for FPC soft boards include PI polyimide film and PET polyester film.

- Flexible copper-clad laminates and rigid copper-clad laminates are also moving towards halogen-free and environmentally friendly materials.

- Advantages and disadvantages of polyester (PET) resin include acceptable mechanical and electrical properties but poor heat resistance, making it unsuitable for direct welding assembly.

- Adhesives like PI resin, PET resin, modified epoxy resin, and acrylic resin are commonly used to bond copper foil with the base film.

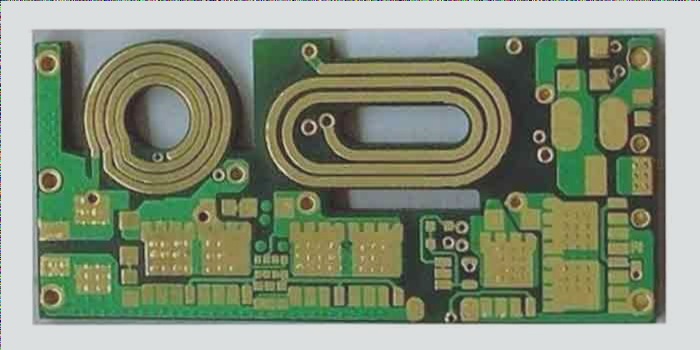

Flexible Copper-Clad Laminates (FCCL)

- FCCL typically has a three-layer structure consisting of polyimide, adhesive, and copper foil.

- A two-layer structure FCCL without adhesive has been developed to enhance electrical performance and dimensional stability.

- New methods of depositing electroplated metal layers on polyimide films are emerging, catering to high-performance requirements of flexible boards.

Liquid Crystal Polymer (LCP) Copper Clad Laminates

- LCP copper clad laminates are created by hot-pressing a thermoplastic liquid crystal polymer film with copper foil, resulting in single or double-sided copper-clad laminates.

- LCP boasts low water absorption and a favorable dielectric constant, making it suitable for high-frequency boards.

- TLCP hot-melt liquid crystal polymer offers advantages like injection molding, extrusion into a substrate for PCBs and FPCs, and recyclability.

Halogen-Free (Bromine) Substrates

- Halogen-free substrates are essential for both rigid and flexible boards to meet flame-retardant and environmental standards.

Conductive Materials

- The primary conductive material in FPC soft boards is copper foil, with additional alloys like aluminum, nickel, gold, and silver also utilized.

- Two types of copper foil, electrolytic and rolled, are used based on production methods, each with unique characteristics.

Conductive Inks

- Conductive inks, primarily silver paste, are used in FPC flexible board manufacturing to create wires or shielding layers.

- Conductive ink graphics offer low resistance, strong bonding, flexibility, and eco-friendly and cost-effective production.

Key Factors in PCB Design

- PCB design plays a critical role in electronic products, ensuring stable circuit performance and overall product quality.

- Effective circuit layout minimizes signal interference and crosstalk, enhancing circuit stability and reliability.

- Analyzing signal transmission paths and avoiding signal crossing and interference are crucial aspects of circuit layout.

Key Considerations for PCB Design

1. Line Width and Spacing

Choosing the right line width and spacing is crucial in PCB design. It not only reduces impedance but also enhances circuit reliability. Tailor these parameters based on signal frequency and power for optimal performance.

2. Grounding Design

Effective grounding design minimizes signal return paths, loops, and interference. A well-planned grounding circuit with reduced resistance is essential in PCB design to ensure signal integrity and minimize noise.

3. Power Supply Design

A stable power supply is essential for circuit functionality. Consider layout and connection methods to minimize common mode voltage, enhancing the circuit’s anti-interference capabilities and overall performance.

4. Temperature Control

Proper temperature control is key to prolonging electronic product lifespan. Layout heat sinks and ventilation holes strategically in PCB design to optimize heat dissipation, prevent overheating, and safeguard circuit components from damage.

5. Bus Layout

Optimizing bus layout in PCB design reduces signal paths, interference, and latency. Carefully plan the signal transmission path, layout the bus system logically, and enhance circuit performance stability.

6. In Summary

By focusing on circuit layout, line width and spacing, grounding, power supply, temperature control, and bus layout, PCB design can greatly enhance the reliability and performance stability of electronic products.