—

With the emergence of miniaturized high-density packaging, the requirements for high-speed PCB boards and high-precision assembly have become increasingly critical. Consequently, related assembly equipment and processes have advanced significantly, offering enhanced flexibility.

Flip-chip technology features a smaller form factor, along with finer ball diameters and pitches compared to BGA or CSP, thereby presenting unprecedented opportunities and challenges in ball placement processes, substrate technology, material compatibility, manufacturing processes, and inspection equipment and methods.

Today, electronic devices are adopting more miniaturized and high-density packaging formats such as multi-chip modules (MCMs), system-in-package (SiP), and flip-chip (FC). These technologies have blurred the boundaries between packaging and secondary assembly. Undoubtedly, the rise of miniaturized high-density packaging has intensified the demand for high-speed and high-precision assembly, prompting advancements in assembly equipment and processes that offer greater flexibility.

Due to flip-chip substrates being relatively brittle silicon, applying excessive pressure during material reclamation and flux dipping processes risks substrate fracture. Additionally, small solder bumps are susceptible to deformation under such pressures. Therefore, it is advisable to employ relatively low mounting pressures. Typically, the recommended pressure is around 150g. For ultra-thin chips, such as those with 0.3mm thickness, mounting pressures may need to be as low as 35g.

—

I have refined the language for clarity and coherence while maintaining the technical accuracy of the original content. Let me know if you need any further adjustments!

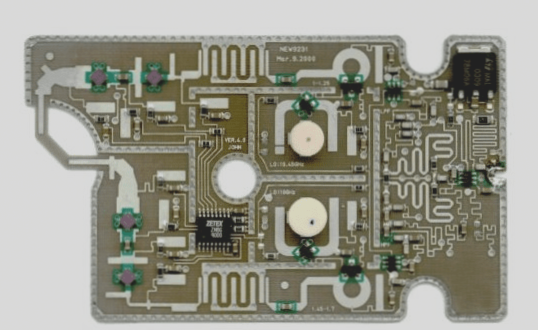

2. For the requirements of placement accuracy and stability, especially for devices with ball pitches as small as 0.1mm, achieving high yield necessitates precise placement accuracy. Factors such as substrate warpage, deformation, the size and positioning of solder mask windows, and machine precision collectively influence final placement accuracy. Here, we focus solely on the machine’s role, excluding discussion on substrate design and manufacture.

3. To address the precision requirements of chip assembly, let’s construct a simplified hypothetical model: 1) Assuming spherical solder bumps on flip-chip PCBs, with circular pads on the substrate of identical diameter; 2) Neglecting effects of substrate warpage and manufacturing flaws; 3) Excluding Theta and shock influences; 4) During reflow soldering, assuming self-alignment where 50% of the solder ball’s contact area can ‘pull up’. Under these assumptions, for a solder ball diameter of 25μm and a 50μm pad size, if the left-right (X-axis) or front-back (Y-axis) positional deviation equals 50% of the pad size, balls consistently align on pads. For flip-chip PCBs with 25μm solder balls, achieving a process capability index (Cpk) of 1.33 requires machine precision of 12μm.

4. Regarding camera and image processing requirements, processing images of fine-pitch flip-chip PCBs necessitates digital cameras with sufficient megapixels. Higher pixel counts provide greater magnification but reduce field of view (FOV), potentially requiring multiple captures for larger devices. Cameras typically employ LED light sources—side, front, or axial—either independently or in combination, tailored to the algorithm’s image needs. For instance, to distinguish one solder ball requires N pixels, and 2N pixels for ball pitch. Universal Instruments’ Magellan digital camera, as an example, uses 4 pixels per solder ball, with images scaled to 75% of actual size. Image processing for flip-chip fiducials parallels that of standard fiducials, with local fiducials often employed alongside global ones.

5. Nozzle selection is critical due to the flat, smooth silicon surfaces of flip-chip PCB substrates. Porous ESD nozzles made from rigid plastic are preferable over rubber nozzles, which may cause device sticking during placement due to aging.

6. The flux application unit plays a vital role in the flux dipping process, ensuring a consistent flux film thickness to facilitate uniform solder ball wetting. Key requirements include: 1) Simultaneous dipping capability for multiple devices to enhance output; 2) Simple, user-friendly design facilitating control and cleaning; 3) Compatibility with a wide range of flux viscosities, ensuring uniform film thickness; 4) Adjustable parameters for dipping process control based on material variations.

7. Feeder requirements are critical for high-speed, high-yield production batches of flip-chip PCBs. Feeding technologies like JEDEC reels, wafer reels, and tape reels demand robust, high-speed performance. Unovis’s bare die feeder (DDF) exemplifies adaptability across various packaging methods and technologies.

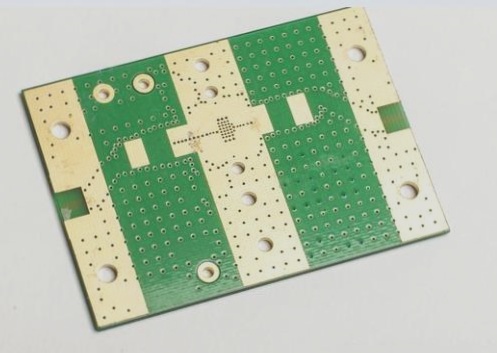

8. Board support and positioning systems are crucial for ensuring flatness and stability, especially with flexible or thin circuit boards. Utilizing carrier plates and vacuum suction systems allows precise Z-direction support adjustment and customizable interface options, crucial for different board types.

9. Post-reflow soldering and underfill curing inspections involve both non-destructive and destructive methods. Non-destructive inspections use optical microscopes, X-ray inspection, electrical tests, and C-SAM to detect defects like solder joint integrity, voids, and underfill completeness. Destructive inspections involve microstructure analysis to identify defects such as cracks, voids, and delamination.

10. Flip-chip PCBs offer advantages in cost, performance, and density, driving their adoption. Ensuring precision, yield, and repeatability remains challenging but is critical across substrate design, assembly equipment, manufacturing processes, and material compatibility.