1. PCB proofing manufacturers should continue to adopt advanced automated production equipment to enhance production efficiency, provide urgent services for users in need, and arrange express delivery for lightning-fast solutions.

2. High cost-performance guarantee: Small-volume circuit board manufacturers should implement a new order management system that supports online pricing, ensuring transparency and helping users feel more cost-effective in their choices.

3. From the above four aspects, it’s clear that small-batch multi-layer PCB circuit board proofing manufacturers can effectively protect users’ rights and interests. Users can also leverage these points to find a suitable service partner in a practical and feasible manner.

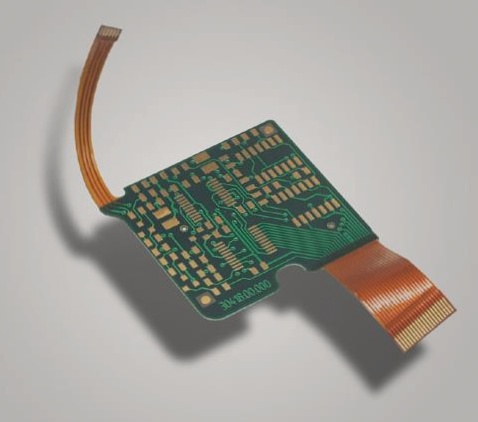

4. The three-proof treatment in PCB board processing refers to “waterproof, moisture-proof, and dust-proof.” After production testing, the PCB circuit board is evenly coated with three-proof paint, which is essential for its durability.

5. Why should we implement the three-proof treatment? The treatment offers several advantages:

6. First, it protects the circuit board: the protective film formed by the three-proof paint effectively isolates the circuit board from harsh environmental damage, enhancing its reliability and safety while extending its service life.

7. Second, it enables higher circuit board integration: the three-proof paint prevents leakage, allowing for higher power and closer spacing between printed boards, which facilitates component miniaturization.

8. Lastly, it improves the appearance of the circuit board: both transparent and colored three-proof paints enhance the aesthetics of printed circuit boards, with the latter providing higher confidentiality by concealing components and PCB design layouts.