Engineering Thermoplastics Overview

-

ABS

ABS, known for its excellent mechanical properties, high impact strength, and heat resistance, is widely used in various applications. Its low density makes it ideal for lightweight uses, often starting with CNC-machined prototypes before mass production through injection molding.

-

Nylon

Nylon, or polyamide (PA), is favored for its exceptional mechanical properties and resistance to impact, chemicals, and abrasion. However, it has a tendency to absorb moisture. Nylon 6 and Nylon 66 are commonly used in CNC machining.

-

Polycarbonate

Polycarbonate, known for its toughness and superior impact resistance, is a versatile thermoplastic used in various applications. It can be clear or tinted, making it suitable for uses like fluidic devices and automotive glazing.

-

POM

Also known as Delrin, POM is valued for its machinability. It is often chosen for CNC machining parts requiring precision, rigidity, dimensional stability at high temperatures, and low water absorption.

-

PTFE

PTFE, commonly called Teflon, offers exceptional chemical and thermal resistance, with the lowest friction coefficient of any solid material. It is heat-resistant and a good electrical insulator, often used as a lining in assemblies.

-

HDPE

HDPE, known for its strength-to-weight ratio and impact resistance, is lightweight and suitable for outdoor and plumbing applications. Like ABS, it is commonly used for prototyping before injection molding.

-

PEEK

PEEK is a high-performance thermoplastic with exceptional mechanical properties, thermal stability, and chemical resistance. It is a strong yet lightweight alternative to metal parts and finds use in various industries, including biomedical applications.

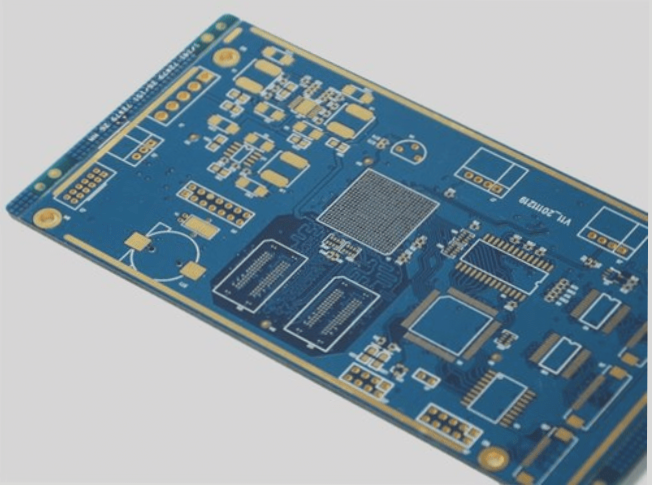

If you have inquiries about PCBs or PCBA, reach out to us at info@wellcircuits.com. Images sourced from the internet.