FPC Circuit Boards: Enhancing Electronics with Flexibility and Reliability

Introduction to FPC Circuit Boards

FPC circuit boards, also known as flexible circuit boards or “soft boards,” are a crucial component in the electronics industry. Made from flexible insulating substrates like polyimide or polyester film, FPCs feature rigid printed circuits that offer a wide range of benefits.

Advantages of FPC Circuit Boards

One of the standout advantages of FPCs is their flexibility, allowing them to be bent, wound, and folded freely. This unique characteristic enables significant reductions in the size of electronic products, supporting trends towards higher density, miniaturization, and enhanced reliability in electronics.

Applications of FPC Circuit Boards

FPCs find extensive use across various sectors, including aerospace, military applications, mobile communications, laptop computers, computer peripherals, PDAs, digital cameras, and more. Their versatility and reliability make them indispensable in modern electronic devices.

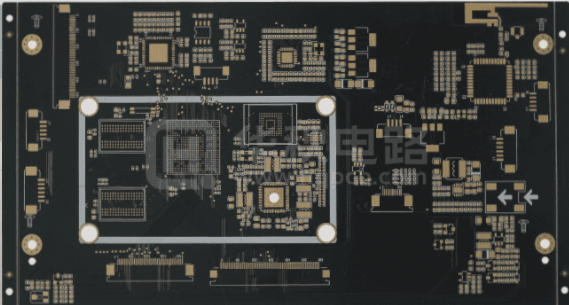

Production Process and Materials

The production process of FPCs is intricate, involving over 20 stages from cutting and drilling to packaging and shipping. Various auxiliary materials are utilized throughout this process to meet customer specifications. The base material of FPCs typically consists of double-sided or single-sided copper foil, which plays a crucial role in determining the board’s electrical performance.

Key Auxiliary Materials for FPC Circuit Boards

- FR4: A flame-resistant material grade used for reinforcement in the welding area of FPCs. It offers stability and reliability during welding processes.

- PI Tape: Made from polyimide film, PI tape strengthens the golden finger area, providing high and low-temperature resistance, acid and alkali resistance, and electrical insulation.

- Steel Sheets: These sheets serve a similar function to FR4 but offer aesthetic appeal and durability. They are used to strengthen the welding area of FPCs.

- TPX Adhesive Film: A high-performance resin barrier release film that aids in the circuit board pressing process, providing glue resistance and plug hole effects.

- EIM Electromagnetic Film: Used for shielding signal interference on the surface of FPCs, EIM electromagnetic film offers electromagnetic interference shielding with low resistance.

- Conductive Adhesive: Essential for connecting and pressing steel sheets and FPCs, conductive adhesive forms an electrical path between materials after curing or drying.

- 3M Tape: Primarily utilized for bonding FR4 and FPCs, 3M tape is crucial for assembling and securing FPCs based on customer requirements.