Flat Cables: The Ultimate Solution for Data Transmission

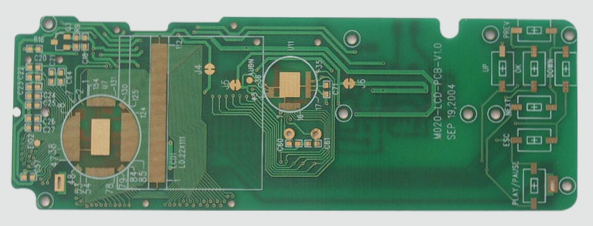

- Flat cables, also known as flexible circuit boards (FPC), are essential for data transmission in dynamic components and active regions, following industry standards such as wiring rules, line sequence, color coding, and numbering.

- Data cables that connect different devices are collectively referred to as flat cables.

- Flat cables are mainly divided into two types: round connectors at both ends (R-FFC for direct soldering) and flat connectors at both ends (FFC for socket insertion).

- They are perfect for data transmission between moving parts and motherboards, as well as for board-to-board connections and compact electronic devices.

- FFC cables are expected to be increasingly used due to their more competitive pricing compared to FPCs.

- FFC can be a suitable alternative in many applications where FPC is currently utilized.

Benefits of Flat Cables in Electronic Devices

- Flat cables can be easily maneuvered, bent, and twisted without compromising their integrity, making them suitable for various shapes and unique package sizes.

- They are ideal for interconnection systems requiring continuous or periodic movement, with the ability to endure millions of dynamic bends.

- Flat cables significantly reduce the size and weight of electronic products, making them perfect for high-density, miniaturized, and reliable electronics.

- They are widely used in aerospace, military, mobile communications, laptops, and other sectors due to their flexibility and space-saving design.

- Flat cables offer a cost-effective solution compared to traditional wiring methods, with FFC being a popular alternative to FPC.

- The compact size and lightweight design of flat cables make them ideal for replacing larger wire harnesses in modern electronic devices.

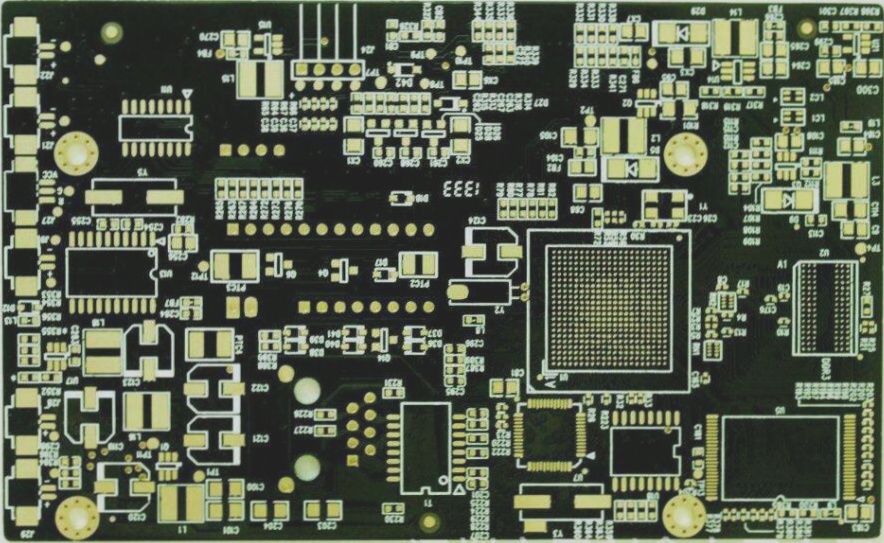

- Flat cables consist of copper circuits or printed polymer thick film circuits on a polymer substrate, offering design flexibility for intricate devices.

- With minimum line width and spacing requirements, flat cables ensure efficient data transmission between components in various devices.

Applications of Flat Cables

- Flat cables are utilized in printers, mobile phones, laptops, and a wide range of electronic devices for efficient data transmission and space optimization.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย